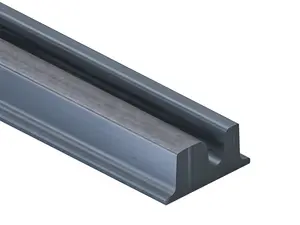

Tram grooved rails

7 variantsIn rapidly growing cities, efficient public transportation is the key to the smooth flow of people and guarantees comfortable travel. Streetcar rail plays an irreplaceable role in this regard, becoming the foundation on which the entire streetcar network rests. These specialized components, designed with durability and safety in mind, create routes that connect different corners of cities, enabling fast and efficient transportation.

We offer two main types of streetcar rails to suit the diverse needs of urban infrastructure: block streetcar rails and grooved streetcar rails. Each of these types is characterized by unique construction and application, guaranteeing optimal solutions for different operating conditions.

Characteristics of tramway rails

Streetcar rails are a key infrastructure component of tramway systems, performing both load-bearing and conductive functions. There are two main types of rails used in streetcar systems: block and grooved.

Block streetcar rails are typically used in areas where greater load resistance is needed. They are characterized by a solid profile, which provides much greater mechanical strength and track stability. Grooved streetcar ra ils, on the other hand, have a groove cut into their surface, allowing the trackbed to be integrated into the road surface, which is particularly useful in urban environments.

The production of streetcar rails is mainly carried out through a hot-rolled steel process, which guarantees their high strength and durability. The steel used in the production of rails is of the highest quality, and is often supplemented with additional elements such as manganese and silicon, which increases its resistance to abrasion and corrosion.

Characteristic of tram-type rails is their adaptation to specific operating conditions, such as frequent bending under streetcar traffic and extreme weather conditions. The rails are also designed to minimize noise and vibration, which is particularly important in urban environments.

Features and advantages of streetcar rails

Features of streetcar rails:

- High strength - resistance to high mechanical loads.

- Durability - resistance to abrasion and corrosion.

- Flexibility of application - ability to integrate with different types of road surfaces.

- Minimization of noise and vibration - ensuring the comfort of users and the environment.

Advantages of tramway rails:

- User comfort and safety - track stability and accident reduction.

- Environmental protection - reduction of noise and vibration emissions.

- Operating economy - longer service life, lower maintenance costs.

Tramway rail profiles

We offer streetcar rails with profiles LK1, 59R2 and 60R2.

LK1

Features:

- Low profile height.

- lightweight construction.

Advantages:

- Optimal for applications where minimal interference with urban infrastructure is required.

- Easy integration into existing pavements.

Disadvantages:

- Less robust compared to heavier profiles.

- Less suitable for heavy streetcar traffic.

59R2

Features:

- Medium profile height.

- Good balance between strength and weight.

Advantages:

- Versatility of application.

- Good load-bearing properties.

- Relatively easy installation.

Disadvantages:

- May require additional reinforcement in high traffic areas.

60R2

Features:

- Higher profile.

- Increased durability.

Advantages:

- Ideal for areas with heavy streetcar traffic.

- Higher durability.

Disadvantages:

- Higher weight, requiring more robust substructure.

- Potentially more difficult to install.

Steel grades

We offer tramway rails made of R260, R200, R290GHT, R290V and R340GHT steel.

R260

Features:

- Carbon steel, good hardness.

Advantages:

- Abrasion resistance.

- Versatility of applications.

Disadvantages:

- Limited resistance to cracking at low temperatures.

R200

Features:

- Lower carbon content, lower hardness.

Advantages:

- Greater flexibility, less prone to cracking.

Disadvantages:

- Faster wear under heavy use.

R290GHT

Features:

- High-carbon hardened steel.

Advantages:

- Exceptional wear resistance.

- Extended service life.

Disadvantages:

- Higher production cost.

- Greater brittleness compared to other grades.

R290V

Features:

- Carbon steel with vanadium additives for improved strength.

Advantages:

- Resistance to abrasion and fracture.

- Improved durability.

Disadvantages:

- Higher production costs.

- Potential difficulties in machining.

R340GHT

Features:

- High carbon content - provides improved hardness and strength.

- Increased wear resistance due to heat treatment processes.

Advantages:

- Longer rail life.

- Resistance to extreme conditions - rails made of R340GHT better withstand harsh operating conditions such as high loads and temperature changes.

- The high strength of R340GHT steel reduces the need for frequent maintenance work.

Disadvantages:

- Higher production costs.

- High hardness can lead to increased brittleness, requiring precise machining and design.

Tramway rail applications

Block streetcar rails are preferred in situations where higher strength and track stability are required. They tend to be heavier and have a full profile, which provides better load-bearing properties. They are mainly used on routes with heavy streetcar traffic and in areas where resistance to intense loads is required.

Grooved streetcar rails are characterized by a groove on the surface of the rail, which allows integration of the track with the road surface. They are ideal for use in urban environments where it is necessary for the tramway track to coexist harmoniously with other forms of transportation. These rails minimize the impact on existing road infrastructure and are often chosen for areas with heavy pedestrian and vehicular traffic.

Advice for investors

- Analysis of needs and requirements - determine the type of traffic (intensity, weight of vehicles) and environmental conditions (climate, topography) to select the right type of rail.

- Evaluate long-term costs - analyze the cost of purchase, installation and future maintenance of the rails, taking into account their service life and required maintenance.

- Consideration of environmental aspects - selection of environmentally friendly materials and solutions that minimize the impact on the environment.

Storage of tramway rails

Proper storage of streetcar rails is key to maintaining their quality and functionality. Our recommendations:

- Horizontal storage - rails should be stored horizontally on level and stable sleepers to prevent bending.

- Corrosion protection - rails should be stored in a dry place, away from moisture, to prevent corrosion. If necessary, use protective measures such as oils or anti-corrosion coatings.

- Preservation of access - rails should be arranged in such a way as to provide easy access to each component without having to rearrange others.

Did you know.

- There are many different profiles of streetcar rails, tailored to specific needs and operating conditions.

- Old streetcar rails are often recycled, and new products are created from their steel, contributing to sustainable development.

- Modern rail manufacturing technologies, such as induction hardening, significantly increase their strength and service life.

- Old streetcar rails are sometimes used in artistic and architectural projects, adding unique character to urban spaces.

Streetcar rails - why with us?

Our offer includes streetcar rails of various dimensions, which allows us to tailor the product to the specific needs of the investment. We make sure that each streetcar rail we supply meets the highest quality standards and is adapted to current technical requirements.

We invite you to take a look at our full range of streetcar rails!

FAQ

What does the rail consist of? What is the structure of the rail?

Rail is a complex component, the structure of which is designed to meet the demands of carrying heavy loads and withstand a variety of operating conditions. Here are the main components of a rail:

- Rail head - the upper part that directly contacts the wheel of a railroad vehicle. Its purpose is to transfer the load from the wheel to the rail. It usually has a rounded shape, so it minimizes wear on both the wheel and the rail itself.

- Rail neck - the middle part of the rail, which connects the head to the foot. Its purpose is to provide adequate strength to the rail, allowing it to deform under load without breaking.

- Rail foot - the lower, flat part of the rail, which is in contact with the railroad sleeper. It keeps the rail stable and firmly seated on the sleeper. In the foot there are holes for fixing the rails with screws or other mounting elements.

- Grooves or grooves - some rails are equipped with grooves or grooves, which are used to guide rail cars or provide better contact with the wheel.

Although a rail may seem like a simple component, its design and material are the result of many years of research and experience in the railroad field.

Are rails the tracks?

Rails and tracks are terms that are often used interchangeably, but have different meanings in the context of railroading. A rail is a metal component, usually made of steel, on which rail vehicles run. Rails provide a running surface for the wheels of railroad vehicles and transfer loads from those vehicles to the sleepers.

A track, on the other hand, is a system consisting of two parallel rails laid on sleepers (wood, concrete or steel) and other structural elements such as connectors, bolts and washers. Railroad track can be laid on a variety of substrates: from ballast to concrete slabs.

In short: a rail is a specific component of a railroad track, while a track is a whole system that includes rails and other components. In colloquial language, people often say "tracks" with "rails" in mind, but in the rail industry the two terms have clearly defined meanings.