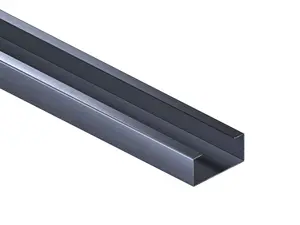

Semi-hollow channel sections

10 variantsSmall channels

11 variantsUPE Channels

32 variantsUPN Channels

46 variantsIn the world of construction, a steel channel is an essential element that combines strength and versatility. We offer a wide selection of channel sections that are not only strong, but also flexible in application.

Our range of channels is as diverse as your needs. Are you looking for a small channel bar that is perfect for delicate structures? Or do you need a UPE channel bar that can easily handle even the most difficult construction tasks? Are you looking for a UPN channel bar, whose robust construction and exceptional strength will meet the expectations of even the most demanding projects? Whatever your needs, we have a steel channel that will meet your expectations.

Characteristics of channels

UPE and UPN channels are specific steel profiles, which, thanks to their unique design features, are becoming an indispensable element in many steel structures.

UPN channels, often referred to as standard steel channels, have a U-like shape with rounded inner edges. They are produced in a variety of sizes, allowing for versatile use.

UPE channels, on the other hand, although similar in form to UPN, are characterized by a more uniform and rectangular shape. Due to this peculiarity, UPE channels offer a slightly different range of mechanical properties and may be preferred in specific applications where a certain regularity of dimensions is required.

The method of manufacturing steel channels is based on the hot-rolling process. The steel, initially in solid form, is heated to a very high temperature and then passed through specially designed rolling mills that shape it into the desired channel profile. This process guarantees excellent homogeneity of the material, which translates into high strength and durability of the product.

Features and advantages of channel sections

Features of channels:

- UPN steel channel section has a U-like shape with rounded inner edges, which guarantees a certain range of mechanical properties.

- UPE channels are characterized by a more uniform and rectangular cross-section, which allows them to be precisely selected for different applications.

- Both types of channels are manufactured from high-quality steel, which ensures their durability and strength.

- Structures based on steel channels offer excellent material uniformity.

- The variety of available sizes and dimensions allows a wide range of channel applications in various construction projects.

Advantages of channels:

- UPE and UPN channels provide excellent stability and load resistance, making them indispensable in many structures.

- Precision in manufacture and consistency in dimensions ensures ease of installation and consistency in connections.

- The high quality of the steel from which the channels are manufactured ensures long life and resistance to external factors such as corrosion.

- Thanks to its design, UPE and UPN steel channels minimize the risk of deformation during loading, which is crucial in many structural applications.

Steel grades

S235JR steel (1.0038)

Features:

- Low-alloy structural steel with good weldability.

- Contains a maximum of 0.17% carbon in composition.

- It has good mechanical properties at low loads.

Advantages:

- Excellent weldability without the need for additional protective measures.

- Good turning, bending and cold processing properties.

- High ductility and good fracture toughness.

- Relatively low production cost compared to other steels.

Disadvantages:

- Lower strength compared to higher quality steels such as S355J2.

- May require surface treatment to provide adequate corrosion protection in some applications.

S355J2 steel (1.0577)

Features:

- Low-alloy structural steel with improved strength.

- Contains small amounts of carbon, manganese, silicon, phosphorus and sulfur.

- It has higher tensile strength compared to S235JR.

Advantages:

- High strength and hardness, making it an ideal choice for structures subjected to heavy loads.

- Excellent weldability and ease of heat treatment.

- High impact resistance, even at low temperatures.

- Ability to achieve higher performance in structures with less material weight.

Disadvantages:

- Higher cost compared to S235JR steel.

- In some applications, may require additional hardening or heat treatment to achieve desired mechanical properties.

Applications of channels

Channels are a key component of many steel structures, serving an important function in providing strength and stability. These steel sections are often used where load-bearing strength needs to be combined with aesthetics, and where load distribution is required in structures.

UPE steel channels are often preferred in areas where greater precision in dimensions is required. Thanks to their design, UPE channels provide optimization in bending resistance, making them an ideal choice for structures that require uniform force distribution. In addition, their shape makes them easier to install in areas with limited access.

UPN channels, on the other hand, provide better dynamic load distribution properties due to their U-like shape with rounded inner edges. Such channels are often used in structures where concentrated load transfer is required, such as bridges and supports. In addition, the rounded inner edges of UPN channels minimize the risk of point stresses, resulting in better fatigue strength.

Advice for investors

- Determine exact requirements - before making a purchase, determine the specifications and dimensions of UPE and UPN channels that will best meet the requirements of your project.

- Quality of steel - make sure the supplier uses high quality steel that meets industry standards to ensure adequate product durability and strength.

- Certifications and documentation - request technical documentation and quality certificates that confirm the mechanical and chemical properties of the channels offered.

- Transportation options - think about logistics. Some suppliers offer favorable transportation solutions, which can affect the final cost of your investment.

- Specific application - make sure the channel bar you choose is suitable for a specific application. For example, UPN channels may be better for areas with concentrated loads, while UPE may be preferred where greater precision is required.

Storage of channel sections

- Proper storage of steel channels is key to maintaining their quality and functionality. Our recommendations:

- Horizontal storage - channels should be stored horizontally on level and stable supports to prevent bending.

- Spacing between supports - to avoid deformation, supports should be placed at regular intervals to ensure that the weight of the channels is evenly distributed.

- Protection from corrosion - store channel sections in a dry place and protect them from the weather, such as rain or snow. Use tarps or other protective materials if open-air storage is unavoidable.

- Stack spacing - leave adequate spacing between stacks of channel sections to ensure adequate ventilation and easy access for loading equipment.

- Regular inspection - carry out regular inspections of the condition of channel stacks, especially for corrosion, mechanical damage or other irregularities.

- Prevent contact with chemicals - avoid storing channel sections in close proximity to chemicals that may cause corrosion or other reactions with the metal.

Did you know

- The word "channel" comes from the shape of the letter "C", which resembles the cross-section of many channels, especially those with a standard profile.

- Although channels are commonly associated with construction and steel structures, they are also used in industries such as automotive, railroad and engineering.

- The geometry of channel sections is designed to provide an optimal ratio of strength to material weight. As a result, channels provide structural strength while saving material.

Channels - why with us?

Our offer is a wide selection of channel sections that will meet all your needs. Whether you need a small channel for a delicate structure or a robust UPE or UPN channel for heavy-duty areas, we will always provide you with the right solution.

Get acquainted with our range of channel sections now, and if you have questions, our specialists are always at your service.

You are welcome!

FAQ

What is the difference between UPE channel section and UPN channel section?

UPE and UPN channels are types of steel sections used in various structures. Both types have a "U" shaped profile, but differ slightly in construction and application.

UPN channel section, also known as normal section, has a narrower profile and shorter wings compared to UPE channel section. In addition, UPN channels have wings inclined at a certain angle, which is a characteristic feature of this type of profile. They are used where greater strength is required while maintaining lower weight.

On the other hand, UPE channels, called parallel wing sections, have a wider profile and longer, parallel wings. Such channels are used where greater load-bearing capacity and strength are needed, such as in industrial construction and bridge structures.