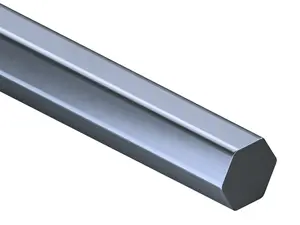

Stainless hexagonal

17 variantsThe variety of forms and shapes of steel products available on the market is astounding, and one of the unique and practical products we can offer is the steel hexagon. Why should you pay attention to hexagonal bars? First of all, because of their versatility of application and simplicity of processing.

Characteristics of hexagons

In the metal industry, a steel hexagon is a special form of metal that is drawn to produce bars with a characteristic hexagonal shape. Hexagonal bars are formed by pulling them through dies of a certain shape, which allows for accurate dimensions and a uniform surface.

The process of manufacturing a hexagonal steel bar begins with the selection of the right quality steel, which is then heated to the right temperature. This steel then undergoes a drawing process in which it is pulled through hexagonal dies to obtain the desired shape and dimension. Quality control plays a key role in this process to ensure that each steel hex bar meets certain standards and technical requirements.

A key feature of hexagonal bars is their high dimensional precision and uniformity of structure. Due to their shape, these bars have certain advantages that round bars lack, such as better mechanical properties, increased contact area. It is important to pay attention to the quality of the steel and the production process, so that the product becomes corrosion-resistant and durable.

Features and advantages of hexagons

Features of drawn hexagons :

- Hexagonal bars have a uniform and precise geometry through the entire length of the product.

- High dimensional precision to meet stringent quality standards.

- Smooth surface without burrs or irregularities, which is the result of the drawing process.

- The steel hexagon is characterized by a uniform crystal structure, resulting in better resistance to cracking and mechanical damage.

- Customizable mechanical properties by choosing the right steel quality and heat process.

Advantages of drawn hexagons:

- Steel hexagonal bar has an increased contact area compared to round bars, which is advantageous in many industrial structures.

- Better mechanical properties due to the homogeneous structure and drawing process.

- Ability to achieve higher tensile strength and yield strength.

- Hexagonal steel is easier to machine, which speeds up production time and reduces costs.

- Minimal need for surface treatment due to the smooth surface achieved by the drawing process.

- Excellent corrosion resistance due to homogeneous structure and lack of surface irregularities.

Steel grades

We offer hollow sections made of 11SMN30+C (1.0715), C45+C (1.0503), C45E+C (1.1191), S235JRC+C (1.0122) and S355J2C+C (1.0579) steels.

11SMN30+C (1.0715)

Features:

- Automated, unalloyed steel with low carbon content and nitrogen and sulfur addition.

- It is characterized by good thermal conductivity.

Advantages:

- Excellent machinability due to sulfur and nitrogen content.

- Hardens well.

Disadvantages:

- Lower strength compared to some other steels.

C45+C (1.0503)

Features:

- Medium-carbon steel, quite hard after hardening.

Advantages:

- Possibility of high strength and hardness after heat treatment.

- High resistance to wear.

Disadvantages:

- More difficult to machine compared to low-carbon steels.

- Requires careful hardening process to avoid cracking.

C45E+C (1.1191)

Features:

- Similar to C45+C, but with higher chemical purity, resulting in better mechanical properties.

Advantages:

- High strength and hardness.

- Excellent wear resistance.

- Better weldability than C45+C.

Disadvantages:

- Higher cost compared to C45+C.

- Requires precision heat treatment.

S235JRC+C (1.0122)

Features:

- Low-carbon structural steel with basic strength.

Advantages:

- Good weldability.

- Machinable well by machining.

Disadvantages:

- Lower strength compared to high-carbon steels.

S355J2C+C (1.0579)

Features:

- Structural steel with higher strength compared to S235JRC+C.

Advantages:

- Good weldability.

- High strength.

- Hardens well.

Disadvantages:

- May require special machining compared to lower strength steels.

- Higher cost compared to S235JRC+C.

Applications of hexagons

In the metal industry, hexagons are often used as raw materials in various manufacturing processes. They are widely used in the manufacture of machine components, tools, and as components in a variety of structures.

Drawn hexagonal bars, due to their high dimensional precision and uniform structure, are widely used in the automotive and aerospace industries and in the production of precision machine parts. Hexagonal steel bar is also popular in the construction sector, where it is used as connecting elements or as the basis for specialized structural components. In addition, hexagonal steel bar is used as a raw material in the tooling industry, where its shape and mechanical properties are essential for producing tools with high strength and accuracy.

Tips for investors

- Make sure the steel hexagonal bar you choose meets all standards and quality standards appropriate to your industry and application.

- Carefully determine the required mechanical properties of hex bars, such as strength, hardness or corrosion resistance, to ensure their optimal performance in your construction process.

- Make sure that the selected hexagonal steel bar is suitable for machining if you are planning further work such as turning, milling or welding.

- Check the availability of technical documentation for the selected hexagonal bars, such as quality certificates, chemical composition analysis or test protocols.

- Make sure the supplier is able to deliver the hexagonal bars in the quantities and dates you require, so as not to disrupt the production process.

- Regularly monitor the quality of supplied steel hexagons to ensure production continuity and consistency.

Storage of hexagons

Proper storage of steel hexagons is key to maintaining their quality and functionality. Our recommendations:

- Storage stability - make sure hexagons are stored on stable and level surfaces to prevent the material from tipping over or becoming distorted.

- Protection from the elements - store the hexagons in a dry and well-ventilated room, protecting them from moisture, corrosion and direct sunlight.

- Distance from the wall - maintain at least 30 cm distance between the hexagons and the walls of the warehouse to ensure adequate air circulation.

- Protection from mechanical damage - avoid direct contact with heavy equipment such as forklifts and protect the hexagons from possible damage.

- Load distribution - distribute the load evenly across shelves or storage racks to avoid overloading and risking structural damage.

- Inventory rotation - use the "first in, first out" rule to ensure that older hexagons are used before newer ones.

Did you know

- In a hexagon with sides of equal length, all interior angles have a measure of 120 degrees, making it one of the few regular geometric figures.

- Due to their shape, hexagons have the ability to distribute stresses evenly, making them extremely strong in engineering structures. - In nature, hexagonal structures, such as honeycombs, minimize material wear while maintaining maximum strength. Similarly, hexagons in engineering are often used to achieve maximum performance with minimal raw material consumption.

- Hexagons are often used in aerospace structures because of their ability to optimize airflow and minimize drag.

- Hexagons, because of their shape, are often easier to machine, such as in turning processes, than materials with other cross sections, speeding up production and reducing costs.

Hexagons - why with us?

Thanks to the use of hexagonal steel bars, projects will gain in aesthetics and functionality. We offer a wide range of sizes and lengths of hexagons, allowing you to find the perfect product for any application, regardless of its complexity.

Hexagonal bars are extremely versatile. Their use is almost unlimited - from various types of machine parts, to structural components, to finishing details. The application of hexagonal bars is limited only by your creativity.

We invite you to take advantage of our range of hexagonal bars. As experienced steel suppliers, we guarantee that our products are of the highest quality. Our team of experts is always available to help you choose the perfect product for your project.

FAQ

How much does a hexagonal bar weigh?

To calculate the weight of a hexagonal bar, you need to know its length, diameter and the density of the material from which it is made. For steel, the density is usually around 7.85 g/cm³.

The basic formula for calculating the mass of a hexagonal bar is:

mass = length x cross-sectional area x density

The cross-sectional area of a hexagonal bar is calculated from the formula:

cross-sectional area = (3√3 / 2) x (diameter / 2)^2

Note that the dimensions must be consistent. If you use cm as the unit of length and g/cm³ as the unit of density, the result will be in grams. If you use m as the unit of length and kg/m³ as the unit of density, the result will be in kilograms.

Note that these calculations give you an approximate mass. The actual mass may vary slightly depending on the properties of a particular piece of steel.