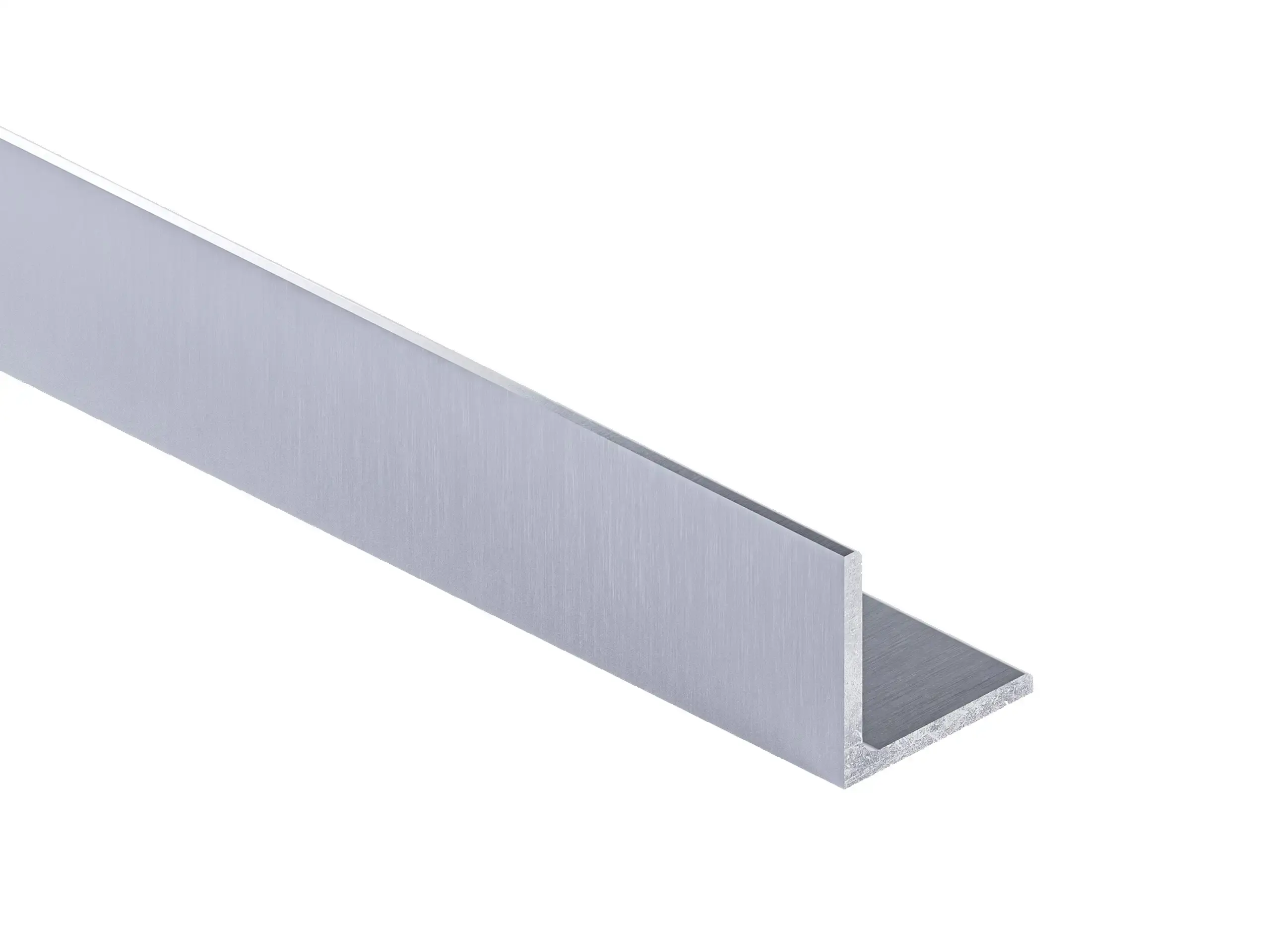

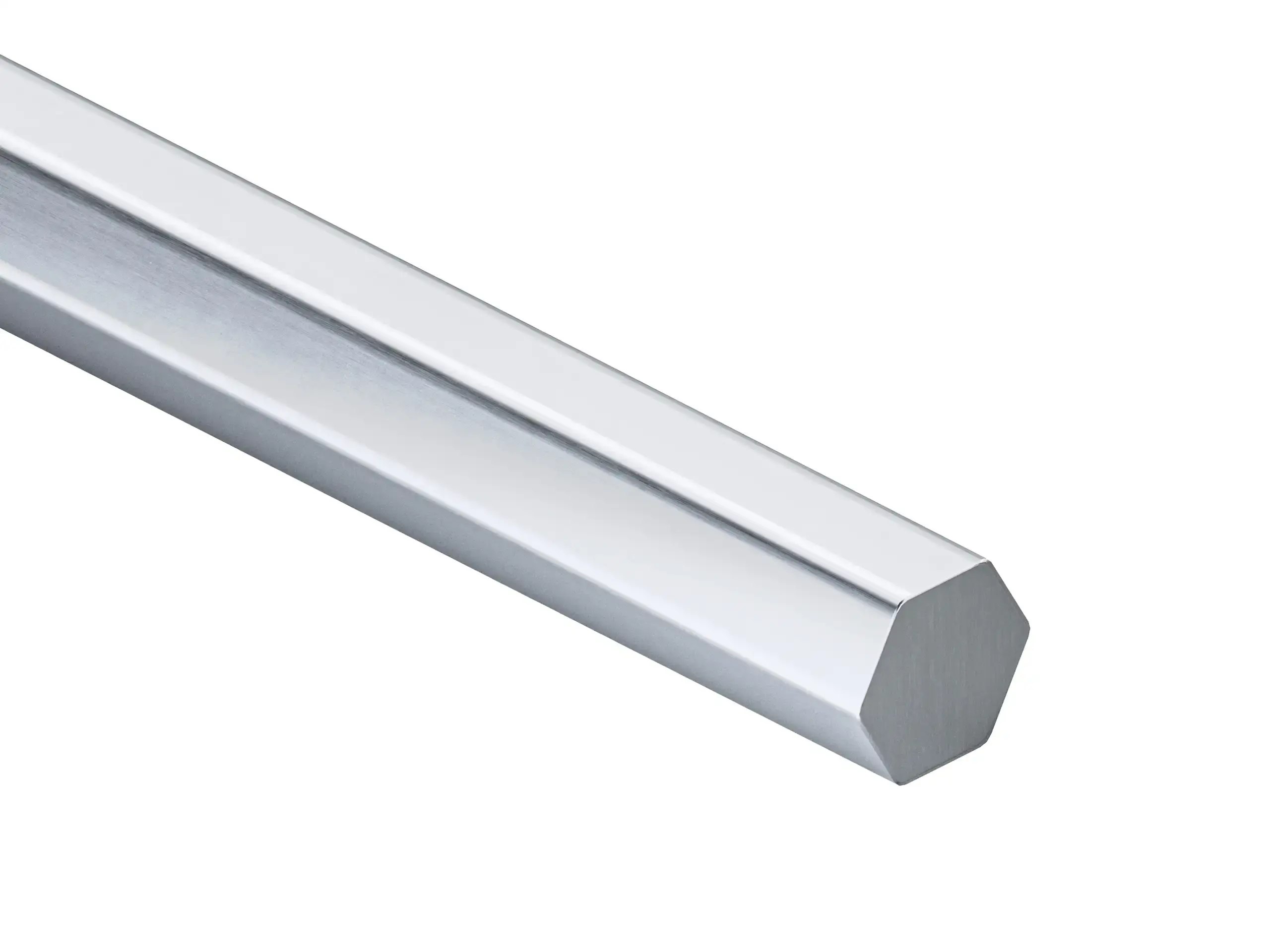

Stainless square bar

Selected variant:

- Steel grade:

- 1.4301/1.4307

- Length - L:

- 3000 [mm]

This is a rendered image. The real product will look different.

Select parameters

Steel grade

Width - B [mm] Please select an option to see price and add to cart

Length - L [mm]

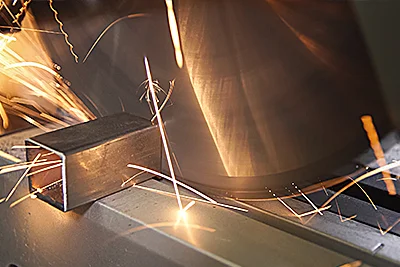

Cutting service

Please log in to add cutting service

Log inAvailable delivery methods

Depending on the weight and length of the ordered products, we offer many convenient delivery methods.

We deliver orders starting from 1 item throughout Poland!

-

Self pick-up

You can collect the goods the next day after paying for the order.

-

Moris Transport

We will deliver the largest orders with our own transport.

-

Moris HDS

Delivery and crane unloading of products up to 7 m in length.

-

Rail transport

We will deliver rails with our own rolling stock. Pricing on individual request.

-

Parcel courier

Contact Customer Service if you would like to order a courier.

-

Pallet courier

We will soon enable the shipment of cut sections on pallets.

You will see the available delivery methods and costs in the cart while placing your order.

Flexible payment methods

Payment on Moris.eu is fast, convenient, and fully secure. We offer modern online payment methods such as Autopay, Apple Pay, Google Pay, BLIK, and card payments. For companies that prefer more traditional solutions, there is also the option of bank transfer based on a proforma invoice. We operate in accordance with international quality management standards – confirmed by the ISO 9001:2015 certificate.

-

Proforma invoice

Advance payment based on an issued invoice

-

BLIK

Mobile payment using a phone

-

Fast transfers

Support for the most popular banks in Poland

-

Digital wallets

Payment using Google Pay and Apple Pay

-

Credit/debit cards

Online payment by card: Visa, MasterCard, and others

Steel grade cross reference

| Steel grade, EN | Steel number | USA AISI | England, BS |

|---|---|---|---|

| X8CrNiS18-9 | 1.4305 | 303 | 303S31 |

| X2CrNi18-9 | 1.4307 | 304L | 304S11 |

| X5CrNi18-10 | 1.4301 | 304 304N |

304S15 304S31 |

Related Products

Description

Grade X2CrNi18-9/AISI 304L

Austenitic corrosion-resistant steel according to the European EN standard is designated X2CrNi18-9, and according to the American AISI/ASTM standard is called 304L.

All corrosion-resistant steels according to the European standard are marked with the first letter X, followed by the carbon content given in hundredths of a % and the main symbols of the alloying elements determining their properties along with their content, i.e. 18% Cr and 9% Ni. In addition, this steel contains C ≤ 0.03%, Mn ≤ 2%, Si ≤ 1%.

Stainless steel, thanks to its single-phase structure, shows resistance to electrochemical corrosion, and after the introduction of at least 8% nickel and 18 chromium, its structure is fully austenitic, characterized by high corrosion resistance and less tendency to grain growth, which has a beneficial effect on the increase in mechanical properties.

Products manufactured from this steel have a very wide range of applications in many industries, but especially in equipment used in the chemical and food industries, they perform well in contact with alcohol, tartaric acid, citric acid, acetic acid, vegetable preparations. They exhibit very good impact strength and ductility, and perform well for use in deep drawing of machine and equipment parts. This steel grade is easily machinable, and due to its low carbon content it is easily weldable, resistant to corrosion in various environments: alkaline solutions, some organic and inorganic acids, natural water, steam. The grade of this steel is most often found in the form of sheets, tubes or bars.

In addition, it is used for finished products that have applications in the construction industry, as components in the petrochemical, automotive, engineering, as well as marine, aviation and railroad industries, and for decorative elements.

X5CrNi18-10 / AISI 304

X5CrNi18-10 steel is a stainless, chromium-nickel, austenitic, corrosion-resistant steel. Thanks to the appropriately selected chemical composition, especially the high content of chromium and nickel, it achieves an austenitic structure, good corrosion resistance in the environment, especially to water and moisture, but without the presence of large amounts of salt or chlorine. It can be subjected to cold forming, cold rolling or forging. It is a well-weldable grade, however, using a maximum welding temperature of about 200 °C. Otherwise, the operation significantly reduces resistance to intergranular corrosion. X5CrNi18-10 steel is used as a decorative material or in many industries, e.g. dairy, brewery, chemical, automotive.

X8CrNiS18-9 / Aisi 303

Stainless steel, austenitic, has the designation X8CrNiS18-9 according to the European EN standard, and according to the American AISI/ASTM standard it is called 303. Thanks to its high chromium and nickel content, it is a corrosion-resistant steel, but the addition of sulfur reduces resistance to intergranular corrosion, and pitting or cavity corrosion may occur. A favorable aspect of sulfur in the chemical composition is improved machinability and cutability. This steel is difficult to weld, poorly suited for cold forming and cold rolling, but can be used in cold drawing. It is most commonly used in the food and dairy industries, the photographic, chemical and textile industries, as well as the automotive and engineering industries.