Seamless tubes

Choose parameters from the matrix below.

This is a rendered image. The real product will look different.

Select parameters

Steel grade

Diameter - Ø [mm] Please select an option to see price and add to cart

Thickness - T [mm] Please select an option to see price and add to cart

Length - L [mm] Please select an option to see price and add to cart

Cutting service

Please log in to add cutting service

Log inAvailable delivery methods

Depending on the weight and length of the ordered products, we offer many convenient delivery methods.

We deliver orders starting from 1 item throughout Poland!

-

Self pick-up

You can collect the goods the next day after paying for the order.

-

Moris Transport

We will deliver the largest orders with our own transport.

-

Moris HDS

Delivery and crane unloading of products up to 7 m in length.

-

Rail transport

We will deliver rails with our own rolling stock. Pricing on individual request.

-

Parcel courier

Contact Customer Service if you would like to order a courier.

-

Pallet courier

We will soon enable the shipment of cut sections on pallets.

You will see the available delivery methods and costs in the cart while placing your order.

Flexible payment methods

Payment on Moris.eu is fast, convenient, and fully secure. We offer modern online payment methods such as Autopay, Apple Pay, Google Pay, BLIK, and card payments. For companies that prefer more traditional solutions, there is also the option of bank transfer based on a proforma invoice. We operate in accordance with international quality management standards – confirmed by the ISO 9001:2015 certificate.

-

Proforma invoice

Advance payment based on an issued invoice

-

BLIK

Mobile payment using a phone

-

Fast transfers

Support for the most popular banks in Poland

-

Digital wallets

Payment using Google Pay and Apple Pay

-

Credit/debit cards

Online payment by card: Visa, MasterCard, and others

Related Products

Description

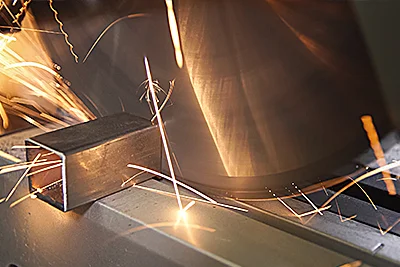

Thick-walled seamless pipes are produced from an ingot heated to rolling temperature and subjected to shaping on a punch press into a molding of circular cross-section. In the next stage, the molded part on a mandrel passes through a pusher bench, changing its length 20 times. After rolling and pulling the mandrel, the product is subjected to rolling on a step reducer until the target dimension is reached.

At the final stage, the tubes are cut to the required length. Part of the produced pipes goes to sales, and part is subjected to drawing to a smaller diameter.

Seamless pipes can be divided into:

- hot-rolled seamless steel pipes

- cold-drawn seamless steel pipes.

The biggest advantage of this type of pipe is very high strength and tightness, as well as resistance to mechanical damage. Seamless ensures the high quality of the finished product and is the most common choice for transporting liquids and gases.

Application of seamless pipes:

pressure and thermal equipment

- construction structures

- machine parts

- automotive and aerospace industries.

S235JRH/P235TR2/P235GH-TC1

A structural steel grade for pressure equipment, used for pipes and tubes in the chemical and food industries, as well as mining and construction.

S235JRH Pipe steels for steel structures, Type S according to EN

P235TR2 Steels for pipes for pressure applications, Type P according to EN

P235GH-TC1 steels for pipes for pressure applications for elevated temperatures - boiler tubes

TC1 and TC2 indicate the category of tests to which the steel is subjected.

The TC1 category depends on:

- the provisions of the standard

- chemical composition (carbon and alloy steels)

- possible choice when ordering pipes (for carbon steels)

The categories differ mainly in the requirement for nondestructive testing of pipes and the choice of possible tests.

Category TC1 includes the following tests:

- melt analysis,

- tensile,

- flattening,

- extrusion or ring stretching,

- impact strength,

- tightness,

- dimensions,

- visual identification of the material,

- and others as agreed.

S355J2H/E355+N/P355NH-TC1

A steel grade used for structural or conduit components for transporting various pressurized media, used in pneumatic and hydraulic power systems, among others.

S355J2H Pipe steels for steel structures, Type S according to EN

E355+N Steels for pipes for machine and equipment parts, steels for pipes for machining according to EN; Meaning of symbols: E - steel for machine parts, 355 - minimum yield strength in MPa, + N - normalizing annealing or normalizing rolling

P355NH-TC1 Fine-grained steels for pipes for pressure applications; Bends for pressure pipelines made of fine-grained steels; Meaning of symbols: P - steel for pressure applications, 355 - minimum yield strength value in MPa, N - normalized delivery condition (normalized annealed or normalized rolled), H - high temperatures.

TC1 and TC2 indicate the category of tests to which the steel is subjected.

TC1 category depends on:

- the provisions of the standard

- chemical composition (carbon and alloy steels)

- possible choice when ordering pipes (for carbon steels)

The categories differ mainly in the requirement for nondestructive testing of pipes and the choice of possible tests.

Category TC1 includes the following tests:

- melt analysis,

- tensile,

- flattening,

- extrusion or ring stretching,

- impact strength,

- tightness,

- dimensions,

- visual identification of the material,

- and others as agreed.