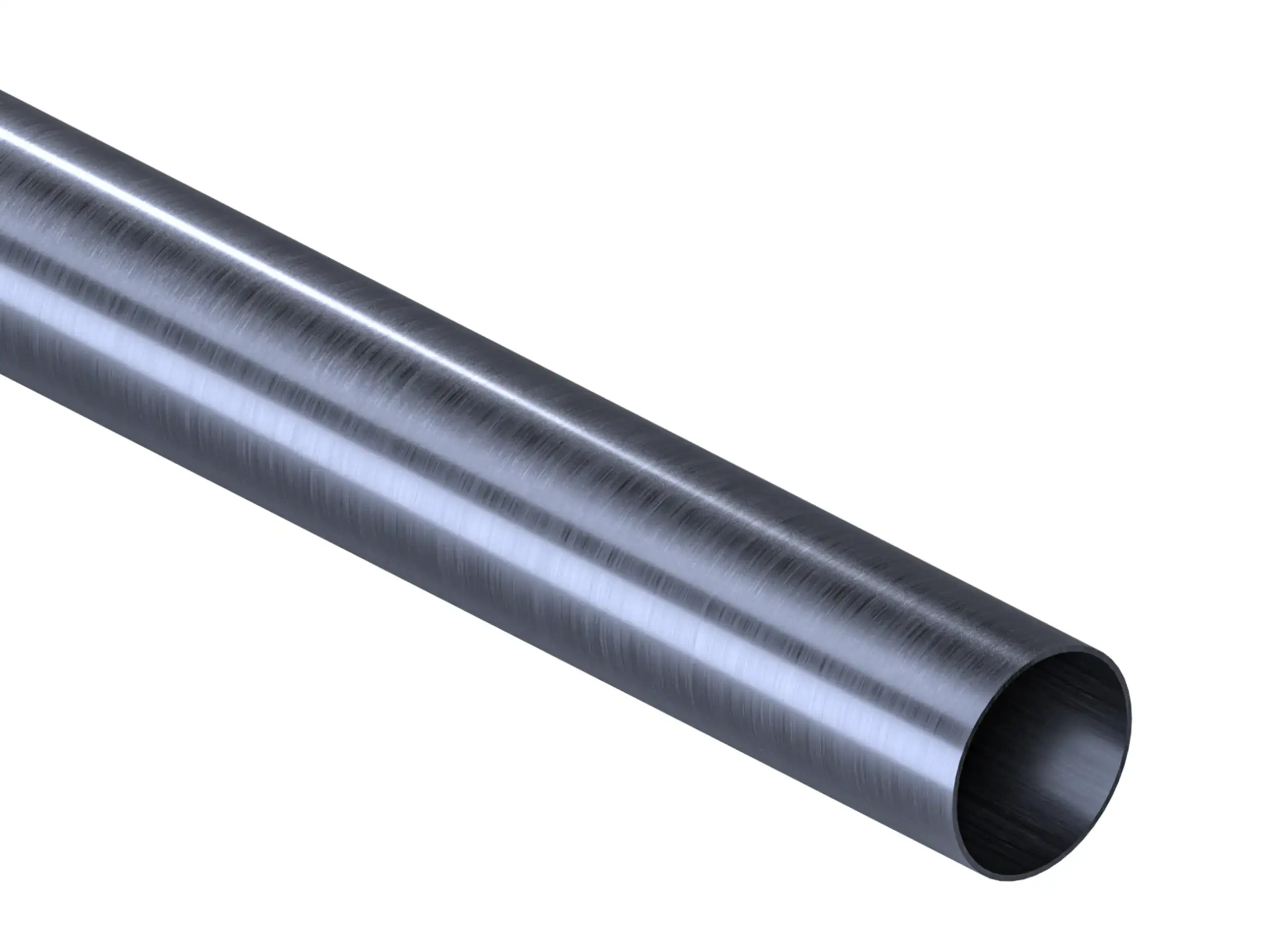

Seamless precision tubes

Selected variant:

- Length - L:

- 6000 [mm]

This is a rendered image. The real product will look different.

Select parameters

Delivery state Please select an option to see price and add to cart

Steel grade

Diameter - Ø [mm] Please select an option to see price and add to cart

Thickness - T [mm] Please select an option to see price and add to cart

Length - L [mm]

Cutting service

Please log in to add cutting service

Log inAvailable delivery methods

Depending on the weight and length of the ordered products, we offer many convenient delivery methods.

We deliver orders starting from 1 item throughout Poland!

-

Self pick-up

You can collect the goods the next day after paying for the order.

-

Moris Transport

We will deliver the largest orders with our own transport.

-

Moris HDS

Delivery and crane unloading of products up to 7 m in length.

-

Rail transport

We will deliver rails with our own rolling stock. Pricing on individual request.

-

Parcel courier

Contact Customer Service if you would like to order a courier.

-

Pallet courier

We will soon enable the shipment of cut sections on pallets.

You will see the available delivery methods and costs in the cart while placing your order.

Flexible payment methods

Payment on Moris.eu is fast, convenient, and fully secure. We offer modern online payment methods such as Autopay, Apple Pay, Google Pay, BLIK, and card payments. For companies that prefer more traditional solutions, there is also the option of bank transfer based on a proforma invoice. We operate in accordance with international quality management standards – confirmed by the ISO 9001:2015 certificate.

-

Proforma invoice

Advance payment based on an issued invoice

-

BLIK

Mobile payment using a phone

-

Fast transfers

Support for the most popular banks in Poland

-

Digital wallets

Payment using Google Pay and Apple Pay

-

Credit/debit cards

Online payment by card: Visa, MasterCard, and others

Related Products

Description

Seamless precision tubes, also known as seamless precision tubes. Thanks to the use of advanced production technologies for E235+N (normalized) and E235+C (cold-crush-hardened / cold-drawn) grades, our offerings meet the needs of the most demanding customers in a wide range of industries.

Characteristics of Products

Seamless precision tubes are distinguished by the following characteristics:

- No welds - the seamless forming process guarantees structural uniformity, which eliminates weaknesses associated with welding.

- Dimensional precision - a tightly controlled manufacturing process ensures the accuracy of dimensional tolerances, making the tubes ideal for applications where high precision assembly is required.

- Compliance with European standards - the pipes meet the requirements of EN 10305-1 standards, which guarantees their quality and safety.

Application

Precision seamless tubes offered by Moris are widely used in the engineering industry for the production of, for example: seat structures, control systems, Cardan shafts, structural components of axles or chassis, springs and air springs, cam shafts, chassis components, drive half-shafts, control components, liquid distributors, dashboard supports.

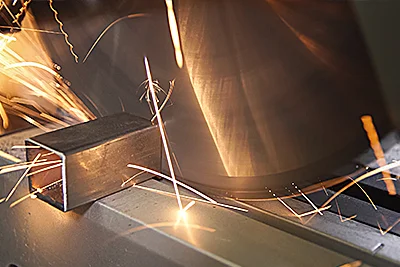

Advanced Manufacturing Process

Moris precision tubing is manufactured in state-of-the-art facilities, where every stage of production is carefully monitored. Products are delivered in condition:

- +N - normalized - means that after cold final drawing processing, the tubes are normalized, i.e. normalizing annealed in a controlled atmosphere, which ensures homogeneity of microstructure, excellent mechanical properties and increased stress resistance.

- +C - cold-cured - cold-drawn tubes, without heat treatment, after the final drawing process; the cold-drawing process allows for greater dimensional accuracy and exceptional surface smoothness.

Rigorous Control Tests

To guarantee the highest quality, our pipes undergo comprehensive quality tests, including:

1.eddy current testing

2.mechanical tests (verification of yield and breaking strength)

3.dimensional and visual inspection

EN 10305-1 standard

The offered cold-drawn pipes comply with the EN 10305-1 standard.