Rebar

Choose parameters from the matrix below.

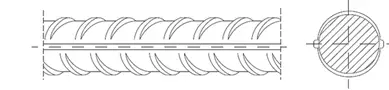

This is a rendered image. The real product will look different.

Select parameters

Steel grade

Diameter - Ø [mm] Please select an option to see price and add to cart

Length - L [mm] Please select an option to see price and add to cart

Available delivery methods

Depending on the weight and length of the ordered products, we offer many convenient delivery methods.

We deliver orders starting from 1 item throughout Poland!

-

Self pick-up

You can collect the goods the next day after paying for the order.

-

Moris Transport

We will deliver the largest orders with our own transport.

-

Moris HDS

Delivery and crane unloading of products up to 7 m in length.

-

Rail transport

We will deliver rails with our own rolling stock. Pricing on individual request.

-

Parcel courier

Contact Customer Service if you would like to order a courier.

-

Pallet courier

We will soon enable the shipment of cut sections on pallets.

You will see the available delivery methods and costs in the cart while placing your order.

Flexible payment methods

Payment on Moris.eu is fast, convenient, and fully secure. We offer modern online payment methods such as Autopay, Apple Pay, Google Pay, BLIK, and card payments. For companies that prefer more traditional solutions, there is also the option of bank transfer based on a proforma invoice. We operate in accordance with international quality management standards – confirmed by the ISO 9001:2015 certificate.

-

Proforma invoice

Advance payment based on an issued invoice

-

BLIK

Mobile payment using a phone

-

Fast transfers

Support for the most popular banks in Poland

-

Digital wallets

Payment using Google Pay and Apple Pay

-

Credit/debit cards

Online payment by card: Visa, MasterCard, and others

Related Products

Description

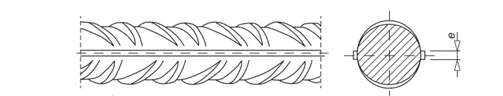

Ribbed reinforcing bars

The construction industry accounts for the largest portion of customers for steel products such as ribbed bars. The design of reinforced concrete structures is currently being carried out in accordance with a new standard that meets the requirements of Eurocode 2.

Ribbed bars are made of reinforcing steel, with a circular or near circular cross-section, as well as a square cross-section and two rows of transverse ribs spaced uniformly along the length of the bar and a longitudinal rib parallel to the longitudinal axis of the bar. Manufacturers of metallurgical products are constantly introducing modern production technologies, thanks to which new and better grades of reinforcing steel are created, characterized by particularly high ductility and high strength.

In accordance with the new standard, a new classification of steel was also created with regard to ductility.

| Class of reinforcing steel | Yield strength fyk [MPa] | Ductility of steel k=ftk/fyk | Strain value εuk [%] |

|---|---|---|---|

| A | 400÷600 | ≥ 1,05 | ≥ 2,5 |

| B | 400÷600 | ≥ 1,08 | ≥ 5,5 |

| C | 400÷600 | 1,15÷1,35 | ≥ 7,5 |

The chemical composition of the steel should be in accordance with the data in Table 2.

| Analysis | Carbon max | Sulfur max | Phosphorus max | Nitrogen max | Copper max | Manganese max | Silicon max | Carbon equivalent value max |

|---|---|---|---|---|---|---|---|---|

| melt | 0,22 | 0,050 | 0,050 | 0,012 | 0,80 | 1,60 | 0,55 | 0,50 |

| product | 0,24 | 0,055 | 0,055 | 0,014 | 0,85 | 1,65 | 0,60 | 0,52 |

The most popular grades of ribbed steel are B500SP and B500B, which differ in the distribution of ribs on the surface of the bar, and thus in adhesion to concrete and ductility.

Application of ribbed reinforcing bars

Ribbed bars are most often used to reinforce elements of concrete structures, such as columns, bays, floor rims, lintel beams at doors and windows, reinforcement of stairs, fences, balustrades and gates. Thanks to their high mechanical properties, they strengthen the load-bearing capacity of the structure and prevent cracking. they are used in the construction of single-family houses, public buildings and industrial facilities, and are also used as a structural part of industrial machinery.

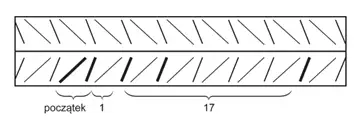

Marking of rebar

Identification of the manufacturer of products should be in accordance with PN-EN 10080:2007 using the method of thickening the cross ribs.

Example

Explanation:

1 - manufacturer's country number

17 - number of the manufacturer's plant

| Country | Country number |

|---|---|

| Austria, Czech Republic, Germany, Poland, Slovakia | 1 |

| Belgium, Netherlands, Luxembourg, Switzerland | 2 |

| France, Hungary | 3 |

| Italy, Malta, Slovenia | 4 |

| United Kingdom, Ireland, Iceland | 5 |

| Denmark, Estonia, Finland, Latvia, Lithuania, Norway, Sweden | 6 |

| Portugal, Spain | 7 |

| Cyprus, Greece | 8 |

| Other countries | 9 |

Steel grades of ribbed reinforcing bars

B500SP

B500SP (according to PN-H-93220:2018) is a grade of special reinforcing steel with increased ductility, used for reinforcing concrete structures, supplied in the form of ribbed bars or ribbed wire rods.

Designation:

B - concrete reinforcing steel / construction steel

500 - yield strength given in MPa

SP - weldable steel; with increased ductility

The characteristic ribs on the bars are arranged in a biaxial manner, this means that they are inclined at two different angles to the axis of the bar as shown in Figure 1 below.

Ribbed bars B500SP are designed for reinforcement of elements and structures designed according to the rules and requirements of Eurocode 2 for ductility class C, such as longitudinal reinforcement, stirrups. they are used for reinforcement of reinforced concrete structures operating under dynamic and repeatedly varying loads. The products should be welded by welding or electric welding. Thanks to its properties, it is used for the most responsible elements of building structures. It exhibits a high deformation value.

The reference document for B500SP ribbed steel bars is the PN-H-93220:2018 standard and the Technical Approval of the Building Research Institute or the Road and Bridge Research Institute.

B500SP steel is certified by EPSTAL or ZETOM + IDBIM, which is awarded only to products with the highest quality and reliability, after testing the adhesion of steel to concrete. The EPSTAL mark is awarded to manufacturers who subject their products to additional statistical control conducted by the Steel Quality Promotion Center. Once certified, the steel is permanently marked, and the EPSTAL mark is rolled into place on the ribs so that the bars can be easily identified under construction conditions.

B500B

B500B is a reinforcing steel grade with medium ductility and a yield strength of 500 MPa, previously known as BSt500S. Due to its ductility, this grade is classified as Class B according to the Eurocode 2 steel classification.

Designation:

B - steel for concrete reinforcement / construction steel

500 - yield strength given in MPa

B - steel with medium ductility

Transverse ribs are arranged in parallel on both sides of the bar, and the rows of ribs form the so-called herringbone, that is, they are arranged in an opposite manner to each other. In addition, the ribs disappear - their height decreases to zero at the point of contact with the longitudinal rib (Figure 2).

B500B ribbed bars are most often used for reinforcement of reinforced concrete structures, working under dynamic and repeatedly varying loads. They should be welded by welding or electric welding.

The reference document for B500B ribbed steel bars is the Technical Approval of the Building Research Institute or the Road and Bridge Research Institute.