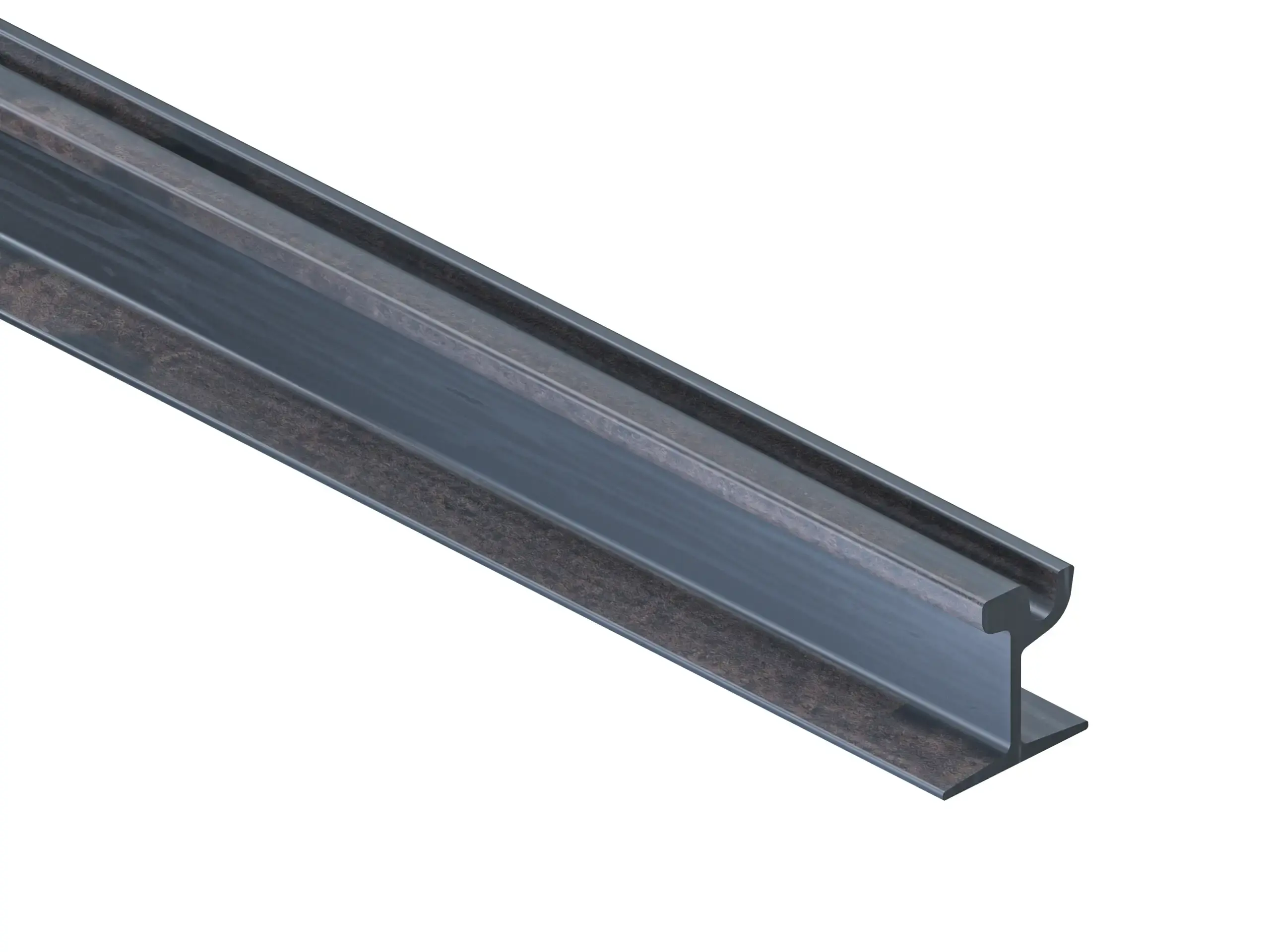

Tram grooved rails

Order online or enquire through the Rail Sales Department.

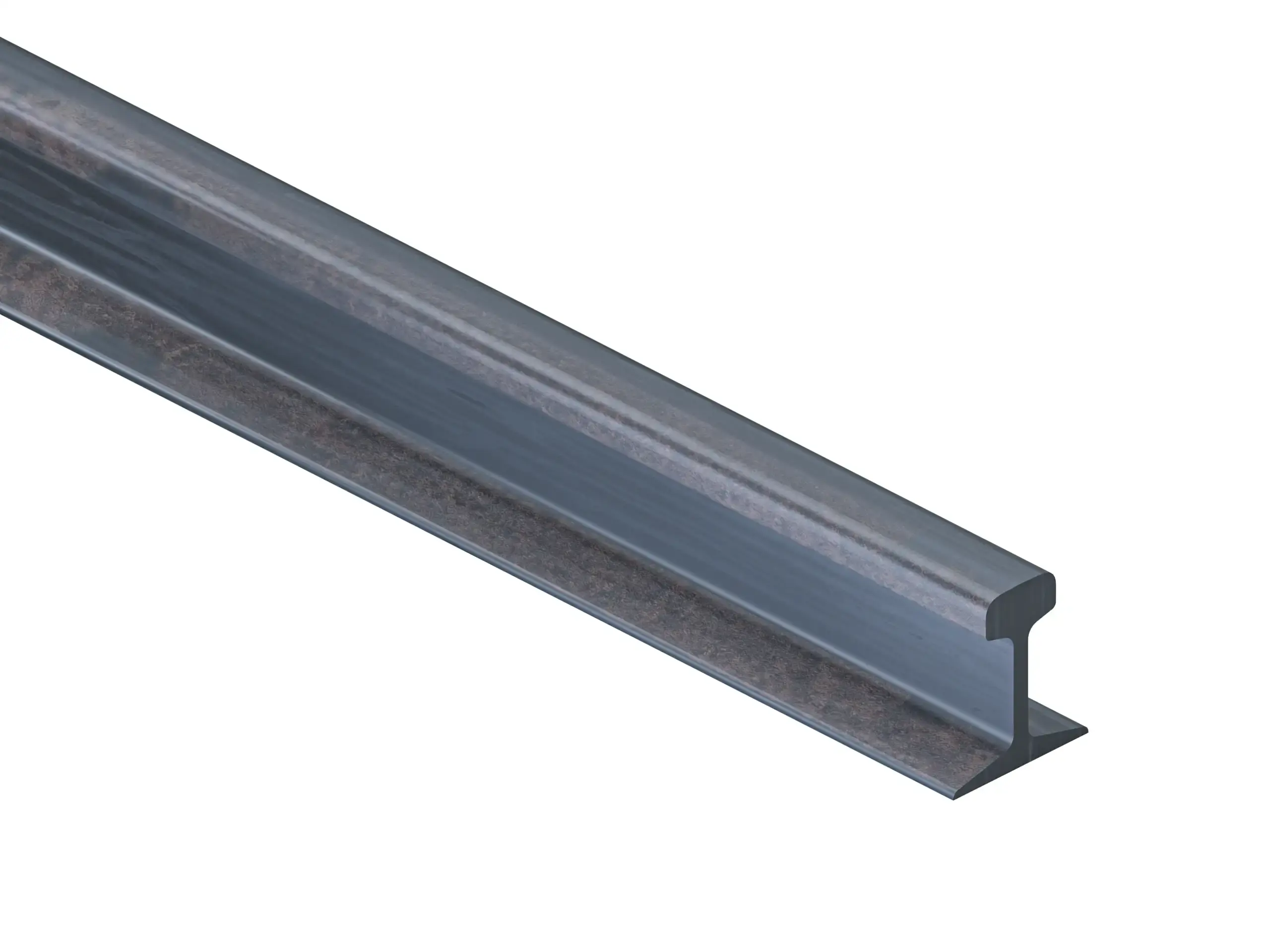

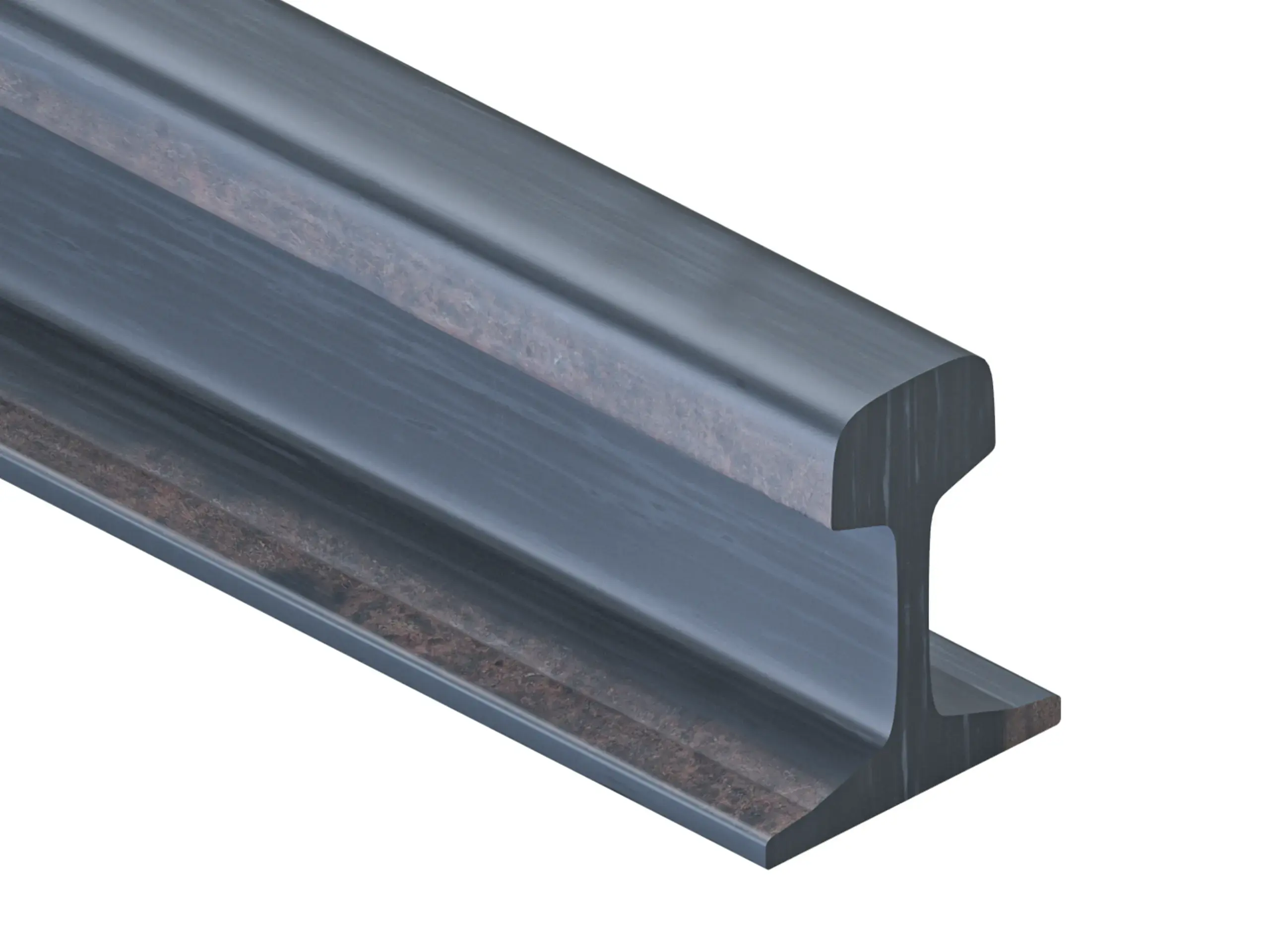

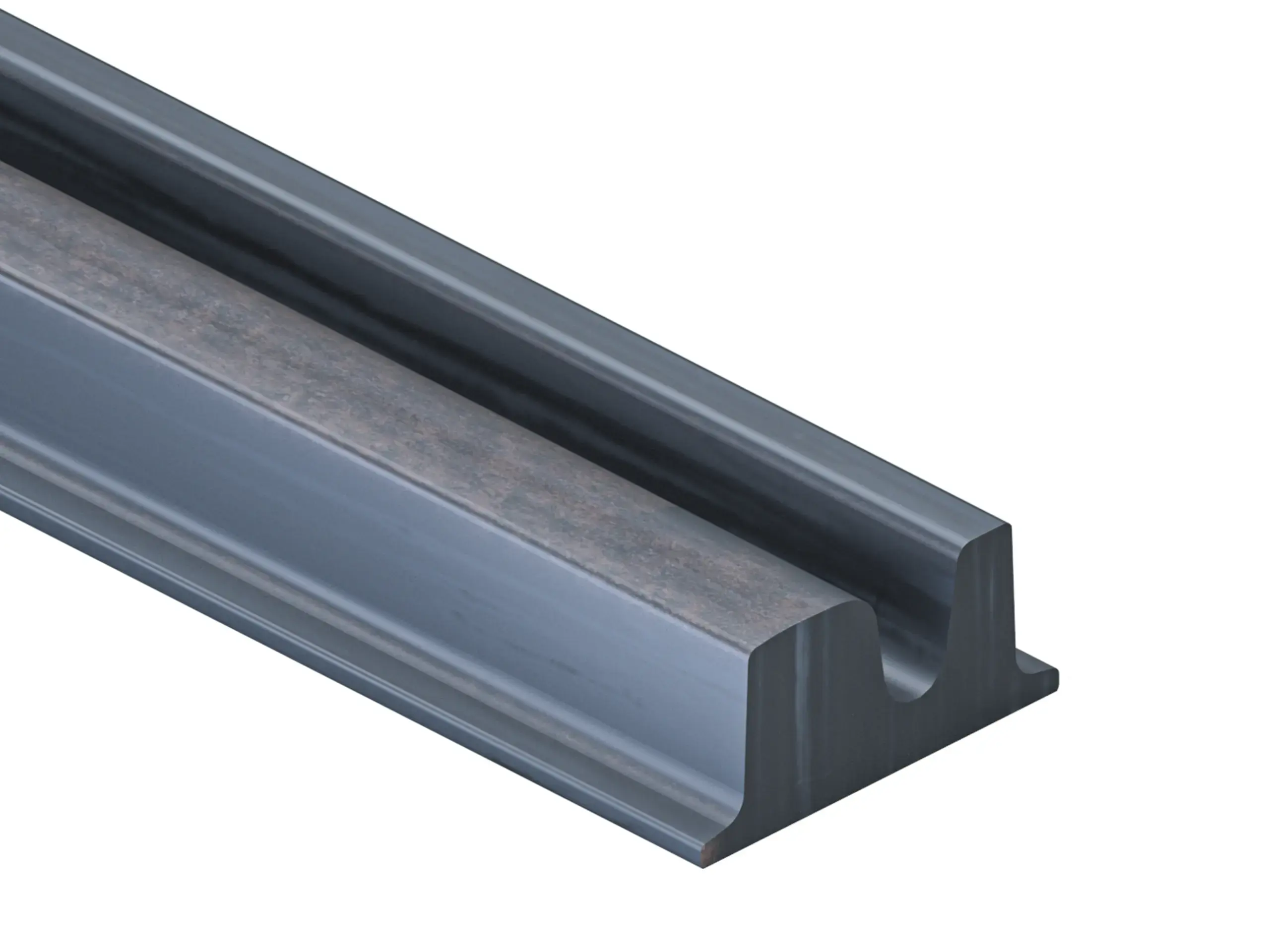

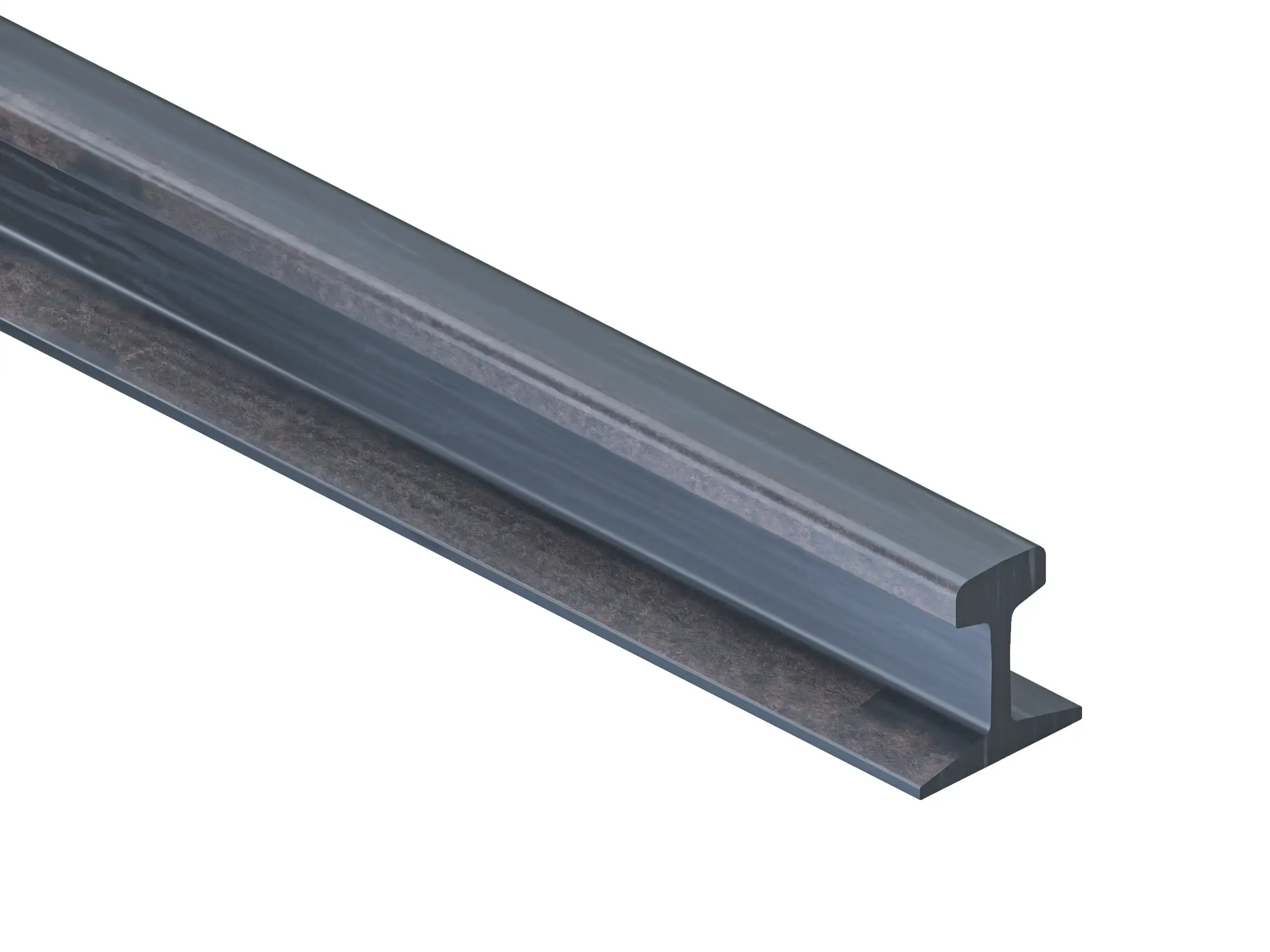

This is a rendered image. The real product will look different.

Select parameters

Rail profile Please select an option to see price and add to cart

Steel grade

Length metr Please select an option to see price and add to cart

About delivery

- Personal pickup:

- If you pick up the rails with your own transport, please note that the rails are loaded from the top at our warehouse, and railway accessories are loaded with a forklift from the side.

- Oversized transport:

Only takes place during night hours (22:00-06:00).

- Transport by Moris:

Provide equipment and personnel for unloading the delivery.

Available delivery methods and costs will be displayed in the shopping cart during the order process.

Available delivery methods

Depending on the weight and length of the ordered products, we offer many convenient delivery methods.

We deliver orders starting from 1 item throughout Poland!

-

Self pick-up

You can collect the goods the next day after paying for the order.

-

Moris Transport

We will deliver the largest orders with our own transport.

-

Moris HDS

Delivery and crane unloading of products up to 7 m in length.

-

Rail transport

We will deliver rails with our own rolling stock. Pricing on individual request.

-

Parcel courier

Contact Customer Service if you would like to order a courier.

-

Pallet courier

We will soon enable the shipment of cut sections on pallets.

You will see the available delivery methods and costs in the cart while placing your order.

Flexible payment methods

Payment on Moris.eu is fast, convenient, and fully secure. We offer modern online payment methods such as Autopay, Apple Pay, Google Pay, BLIK, and card payments. For companies that prefer more traditional solutions, there is also the option of bank transfer based on a proforma invoice. We operate in accordance with international quality management standards – confirmed by the ISO 9001:2015 certificate.

-

Proforma invoice

Advance payment based on an issued invoice

-

BLIK

Mobile payment using a phone

-

Fast transfers

Support for the most popular banks in Poland

-

Digital wallets

Payment using Google Pay and Apple Pay

-

Credit/debit cards

Online payment by card: Visa, MasterCard, and others

Related Products

Description

We offer a wide range of grooved streetcar rails. Our products are characterized by reliability and precision manufacturing, meeting the highest industry standards. We offer a wide range of rail types and lengths to meet the diverse requirements and technical specifications of our customers. With advanced logistics and flexibility in delivery, we guarantee on-time delivery and product availability.

Characteristics of grooved streetcar rails

Grooved streetcar rails are specialized track infrastructure components that play a key role in public transportation. They are characterized by a unique profile, in which an integrated groove is used to guide the wheels of the streetcar. These rails are made of high-quality steel, which ensures their strength and resistance to bending and wear.

The production of grooved streetcar rail begins with the forming of the steel through rolling processes. Each rail undergoes rigorous quality testing, including steel chemical composition analysis and strength testing.

The final product is distinguished by precise dimensions and uniformity of mechanical properties, which is key to ensuring the safety and smoothness of tramway traffic. In addition, special surface treatments, such as hardening, can be applied to increase the durability of grooved tramway rail and its resistance to weather and mechanical stresses.

Features and advantages of grooved streetcar rails

Features of grooved streetcar rails

- Profile with integrated groove: The rails have a unique grooved profile that is used to guide the streetcar wheels, ensuring their proper alignment on the track.

- High-quality steel: Made of high-strength steel, which guarantees resistance to mechanical loads and durability.

- Wear resistance: Special surface treatment increases their durability and wear resistance.

Advantages of grooved streetcar rails

- Streetcar traffic safety: The grooved profile of the rails ensures the stability and safety of streetcars while running.

- Long life: Heavy-duty steel and advanced manufacturing technologies guarantee long rail life and minimize the need for frequent replacement.

- Easily adaptable: Flexibility in design allows for customization to meet the specific requirements of different streetcar systems, facilitating integration into existing infrastructure.

Grooved streetcar rail profiles - 59R2 and 60R2

We offer grooved tramway rails with profiles 59R2 and 60R2.

Steel grades

We offer block streetcar rails in R200, R260, R290GHT and R290V steel grades.

R200 steel grade

Features:

- Low carbon steel with basic alloying additives.

- Tensile strength of about 200 MPa.

Advantages:

- Easy to form and machine.

- Relatively low cost compared to higher grades of steel.

Disadvantages:

- Less load and wear resistance.

- Faster wear in heavily used tramway systems.

R260 steel grade

Features:

- Medium-carbon steel with alloying additives to improve mechanical properties.

- Tensile strength of about 260 MPa.

Advantages:

- Higher load resistance than R200.

- Suitable for moderately operated systems.

Disadvantages:

- More expensive than R200, although it has better properties.

- More difficult to machine than lower grades of steel.

R290GHT (Groove High Toughness) steel grade.

Features:

- High-carbon steel with advanced alloying additives.

- Tensile strength of more than 290 MPa.

- Special treatment for increased strength.

Advantages:

- High abrasion and load resistance.

- Ideal for heavy-duty tramway systems.

Disadvantages:

- One of the more expensive options due to advanced properties.

- Requires precision machining and quality control.

R290V (Groove Vacuum) steel grade.

Features:

- Chemical composition similar to R290GHT.

- Tensile strength similar to R290GHT.

Advantages:

- Ideal for the most demanding applications.

Disadvantages:

- Most expensive option due to advanced manufacturing process.

Applications of grooved tramway rail

Grooved streetcarrail with a 59R2 profile is most often used in lighter streetcar systems, where traffic is less intense and loads are lower. It finds its application primarily:

- in low-traffic urban streetcars - ideal for urban areas with lower streetcar frequency and fewer passengers;

- on track sections with lower traffic volumes - sections such as streetcar line branches, smaller stops or areas with lower traffic volumes;

- in historic and tourist urban areas - places where aesthetic preservation and integration with the surroundings are most important and streetcar traffic is limited.

The 60R2 profile grooved tram way rail is designed for applications that require greater strength and stability, especially in high-traffic tramway environments. It is used:

- on major streetcar lines in large cities - suitable for high-traffic routes where frequent streetcar trips and higher passenger volumes require higher track strength;

- in high-traffic areas - in areas with high streetcar density like city centers, major transportation hubs;

- on streetcar routes with higher speeds - the 60R2 profile provides greater stability and safety when vehicles move faster.

In summary, the 59R2 profile is preferred in less busy environments where integration with the environment and lower traffic intensity is a priority, while the 60R2 profile is chosen in higher traffic areas where greater rail strength and stability are needed.

Tips for investors

- Define technical specifications - define the profile, length and steel grade requirements of the rails to match the technical specifications and operating conditions of the streetcar system.

- Traffic intensity analysis - select a rail profile (e.g., 59R2, 60R2) based on anticipated streetcar traffic intensity and loads on each section.

- Verification of quality and certifications - make sure the rails have the appropriate quality certifications and meet safety standards.

- Evaluate suppliers - choose reputable suppliers that guarantee high product quality and timely delivery.

- Total cost analysis - consider not only the purchase price, but also the cost of installation, maintenance and potential rail replacement.

- Logistics planning - plan delivery logistics to avoid project delays.

Storage of grooved streetcar rails

Proper storage of grooved streetcar rails is key to maintaining their quality and functionality. Our recommendations:

- Maintain proper conditions - store rails in a dry, well-ventilated area to prevent corrosion.

- Lay horizontally - rails should be laid horizontally on specially adapted sleepers to avoid deformation.

- Protection against mechanical damage - provide protection against accidental impacts or other mechanical damage.

- Access to rails - organize the warehouse to provide easy access to the rails.

- Marking and identification - mark each rail or batch of rails to facilitate identification and inventory management.

- Regular inspections - conduct regular inspections of the condition of stored rails to ensure they remain in good condition.

Did you know.

- The first grooved streetcar rails were designed in the 19th century as a response to the need to integrate streetcar tracks into city streets.

- There are many types of grooved rail profiles, each designed for different operating conditions and loads.

- Modern streetcar rails are manufactured using advanced rolling and heat-treatment techniques, which significantly increases their strength.

- Some grooved streetcar rails can last for up to several decades, depending on the intensity of use and environmental conditions.

Grooved streetcar rails - why with us?

When you choose grooved streetcar rails from Moris Wholesale, you gain access to a wide range of products tailored to various needs and technical specifications. Our offer combines the highest quality materials, professional service and flexibility in delivery, which guarantees satisfaction and efficiency in the implementation of your tramway projects. With Moris, you can count on comprehensive support and reliability at every stage - from the selection of suitable rails to their delivery.