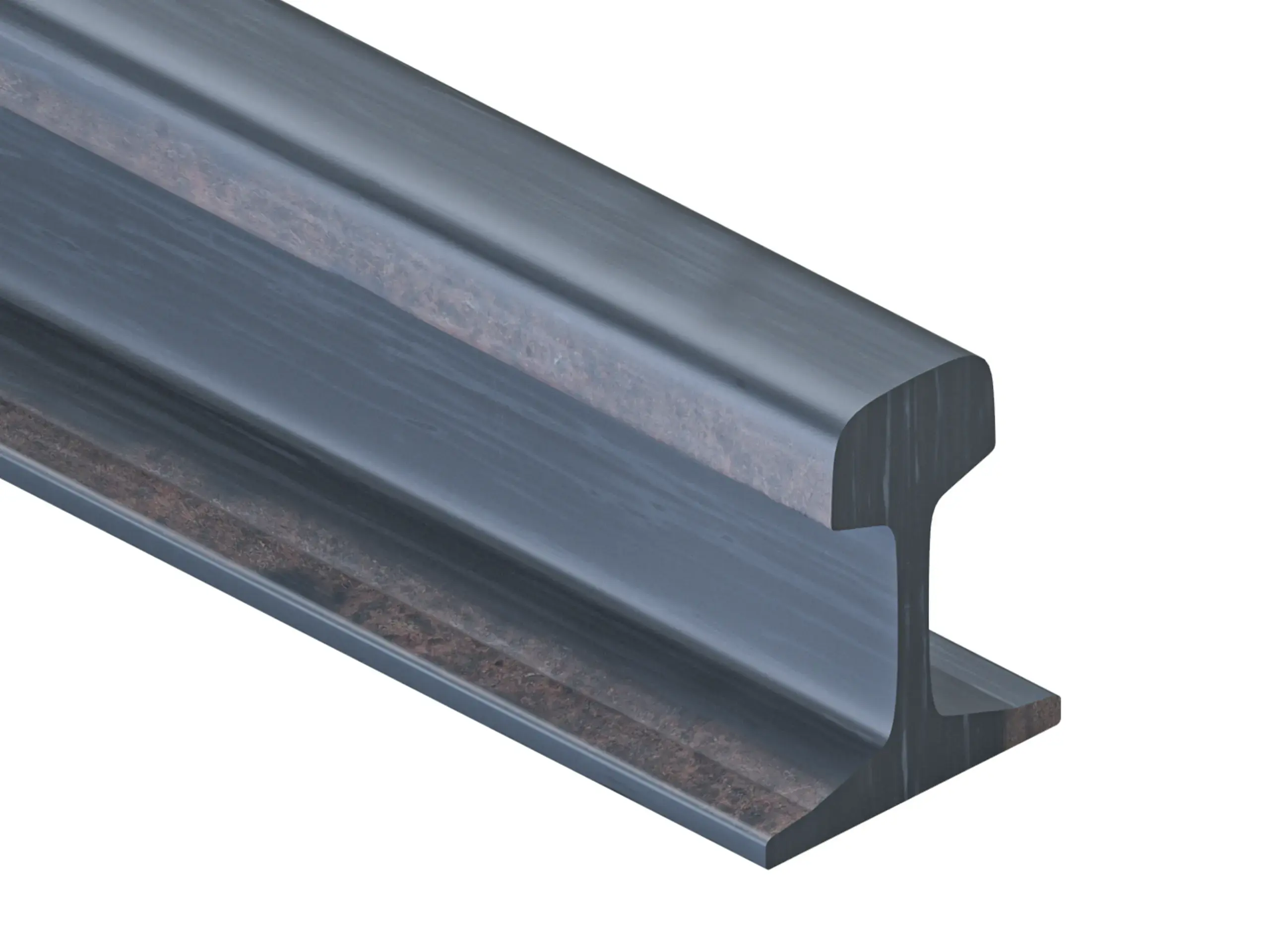

Bolt for railway turnout

Selected variant:

- Nut type:

- Clip bolt

This is a rendered image. The real product will look different.

Select parameters

Type Please select an option to see price and add to cart

Nut type

About delivery

- Personal pickup:

- If you pick up the rails with your own transport, please note that the rails are loaded from the top at our warehouse, and railway accessories are loaded with a forklift from the side.

- Oversized transport:

Only takes place during night hours (22:00-06:00).

- Transport by Moris:

Provide equipment and personnel for unloading the delivery.

Available delivery methods and costs will be displayed in the shopping cart during the order process.

Available delivery methods

Depending on the weight and length of the ordered products, we offer many convenient delivery methods.

We deliver orders starting from 1 item throughout Poland!

-

Self pick-up

You can collect the goods the next day after paying for the order.

-

Moris Transport

We will deliver the largest orders with our own transport.

-

Moris HDS

Delivery and crane unloading of products up to 7 m in length.

-

Rail transport

We will deliver rails with our own rolling stock. Pricing on individual request.

-

Parcel courier

Contact Customer Service if you would like to order a courier.

-

Pallet courier

We will soon enable the shipment of cut sections on pallets.

You will see the available delivery methods and costs in the cart while placing your order.

Flexible payment methods

Payment on Moris.eu is fast, convenient, and fully secure. We offer modern online payment methods such as Autopay, Apple Pay, Google Pay, BLIK, and card payments. For companies that prefer more traditional solutions, there is also the option of bank transfer based on a proforma invoice. We operate in accordance with international quality management standards – confirmed by the ISO 9001:2015 certificate.

-

Proforma invoice

Advance payment based on an issued invoice

-

BLIK

Mobile payment using a phone

-

Fast transfers

Support for the most popular banks in Poland

-

Digital wallets

Payment using Google Pay and Apple Pay

-

Credit/debit cards

Online payment by card: Visa, MasterCard, and others

Related Products

Description

We have a wide range of alloy rail bolts, which allows for a wide configuration of fastening systems depending on individual requirements and technical specifications. We ensure the availability of a wide variety of bolt types, making it easy for our customers to select products perfectly suited to their projects, guaranteeing the reliability and durability of any investment.

Characteristics of alloy rail bolts

Alloy railroad bolts are a key component in the context of railroad track construction and maintenance. Made of high-quality steel alloys, these connecting elements are characterized by exceptional resistance to dynamic loads and resistance to corrosion and abrasion. An important aspect of alloy railroad bolts is their ability to withstand extreme weather conditions and continuous exposure to vibration and impact, which is common in railroad environments.

The production of alloy railroad bolts requires advanced technologies and strict adherence to quality standards. The process begins with the selection of a suitable steel alloy, which is then heat-treated to increase its strength and hardness. The next step is to form the shape of the bolt, which is usually done by hot forging or cold rolling. This allows the thread and head of the bolt to be precisely shaped. After that, the alloy rail bolt is subjected to finishing treatment, including polishing and electroplating, which further increases its resistance to corrosion.

It is worth noting the special design of the alloy rail bolt's thread, which is designed to provide maximum holding power and ease of installation and removal. Such threads must exhibit resistance to loosening under vibration, which is key to maintaining the safety and stability of railroad tracks.

Features and advantages of alloy railroad bolts

Features of alloy railroad bolts:

- Material strength - bolts are made of high-quality steel alloys, which provides them with exceptional mechanical strength.

- Corrosion resistance - the use of advanced surface treatment techniques, such as electroplating, increases the bolts' resistance to weathering and corrosion.

- Precision threading - it is formed with high precision, which guarantees a solid and durable connection of structural components.

- Resistance to dynamic loads - bolts are designed to withstand the high dynamic loads and vibrations typical of the railroad environment.

- High hardness - heat treatment used in the manufacturing process significantly increases the hardness of bolts, which translates into their durability and wear resistance.

Advantages of alloy railroad bolts:

- Increased structural safety - thanks to their high strength and robustness, these bolts significantly contribute to the stability and safety of railroad structures.

- Long-lasting use - high resistance to corrosion and abrasion makes these bolts serve for many years, minimizing the need for frequent replacement or maintenance.

- Flexibility of use - the variety of sizes and types of bolts allows a wide range of applications in many railroad projects.

- Adaptation to extreme conditions - these bolts are designed to withstand extreme weather conditions, which is crucial in the rail industry where safety and reliability are at the forefront.

Types of alloy rail bolts

We offer alloy railroad bolts of the following types: HS32-55, M22X65, M22X72.

HS32-55

Features:

- This is a high strength bolt designed for use in the most demanding railroad environments.

- It has an increased diameter and length, which translates into its ability to handle higher loads.

Advantages:

- Exceptional mechanical strength and hardness guarantee long-term joint stability.

- Ideal for use in areas where exceptional resistance to dynamic loads is required.

Disadvantages:

- Due to its size and specification, it may be less versatile compared to smaller bolts.

M22X65

Features:

- A bolt with a standard diameter of 22 mm and a length of 65 mm, making it suitable for a wide range of railroad applications.

- It features a balanced ratio between strength and flexibility.

Advantages:

- Mainly used for mounting 49E1 rails.

- The diameter and length of the bolt are optimized to ensure a good connection while maintaining economic efficiency.

Disadvantages:

- Despite its versatility, it may not be suitable for applications that require specialized size or strength.

M22X72

Features:

- This is a version of the 22mm diameter bolt, but longer (72mm) for better holding and joint stability.

- An improved version of the M22X65 bolt, offering extra length for increased strength and security . Mainly used for mounting 60E1 rails.

Advantages:

- The increased length of the bolt allows for better load distribution and provides greater connection stability.

- Ideal for applications where additional reinforcement is required without changing the bolt diameter.

Disadvantages:

- Increased length can result in higher manufacturing and assembly costs compared to shorter versions.

Alloy rail bolt applications

Alloy railroad bolts are an indispensable component in railroad infrastructure, performing a key function in ensuring the stability and safety of tracks. Each type of bolt has its own specific application:

- HS32-55 alloy railroad bolts - designed for applications where maximum strength and resistance to extreme loads are required. Their increased diameter and length make them ideal for high-traffic locations where structural safety is a priority. These bolts are often used in the attachment of railroad bridge components, switches or crossing junctions, where structural stability is crucial.

- M22X65 alloy railroad bolts - a versatile solution used in standard railroad structures. Their size is optimally selected to ensure the solid fastening of rails, sleepers or structural elements while maintaining economic efficiency. They are widely used in the construction and maintenance of typical track sections made of 49E1 rails.

- M22X72 alloy rail bolts - thanks to their longer length, they are preferred in situations requiring increased anchorage and stability, especially where ground conditions or loads are more difficult. The use of these bolts is especially recommended in areas where the structure is exposed to higher lateral or dynamic forces, such as track curves, steep hills or frequently used rail-road crossings. The longer length of the bolt provides deeper anchorage, which improves safety and increases the stability of the structure . Mainly used for installation of 60E1 rails

Advice for investors

- Accurate specification of needs - before purchasing, precisely define the project requirements, including loads, environmental conditions and specific technical requirements, to select the right type of rail alloy bolt.

- Material strength analysis - pay attention to the composition and properties of the steel alloys used to manufacture the bolts, as well as the results of strength tests such as tensile, compression and fatigue tests.

- Supplier evaluation - choose reputable suppliers that can demonstrate experience in the rail industry.

- Evaluating total cost - when analyzing the price, consider not only the purchase cost, but also the cost of installation, maintenance, and potential savings from product durability and reliability.

- Purchase planning - due to the variety of bolt types and sizes, plan purchases well in advance to avoid delivery delays, especially for large infrastructure projects.

Storage of railroad alloy bolts

- Proper storage of alloy railroad bolts is key to maintaining their quality and functionality. Our recommendations:

- Control environmental conditions - store bolts in a dry and well-ventilated area to prevent corrosion and material degradation.

- Proper segregation - store screws by size and type to facilitate identification and prevent damage from improper storage.

- Avoid direct contact with the ground - store screws on shelves or pallets to avoid direct contact with moist ground.

- Regularly check the condition - systematically check the condition of stored screws to detect any damage or signs of corrosion early.

Did you know.

- Alloy rail bolts are made from special steel alloys that are tailored to specific technical requirements, such as load or corrosion resistance.

- Advanced techniques such as hot forging and heat treatment are used in the manufacturing process of railroad bolts to increase their strength and durability.

- Special types of threads used in railroad bolts are designed to provide maximum holding power while resisting loosening under vibration.

Railroad alloy bolts - why with us?

Thanks to our wide range of products, we are able to meet all technical needs, even the most specific ones, offering a wide selection of bolts of various types. Our team of specialists provides professional service and expert advice, helping you select the ideal components to meet the individual requirements of each project. In addition, we provide a variety of flexible delivery options throughout Poland, ensuring that the necessary products reach our customers quickly and smoothly.