Baseplate

Order online or enquire through the Rail Sales Department.

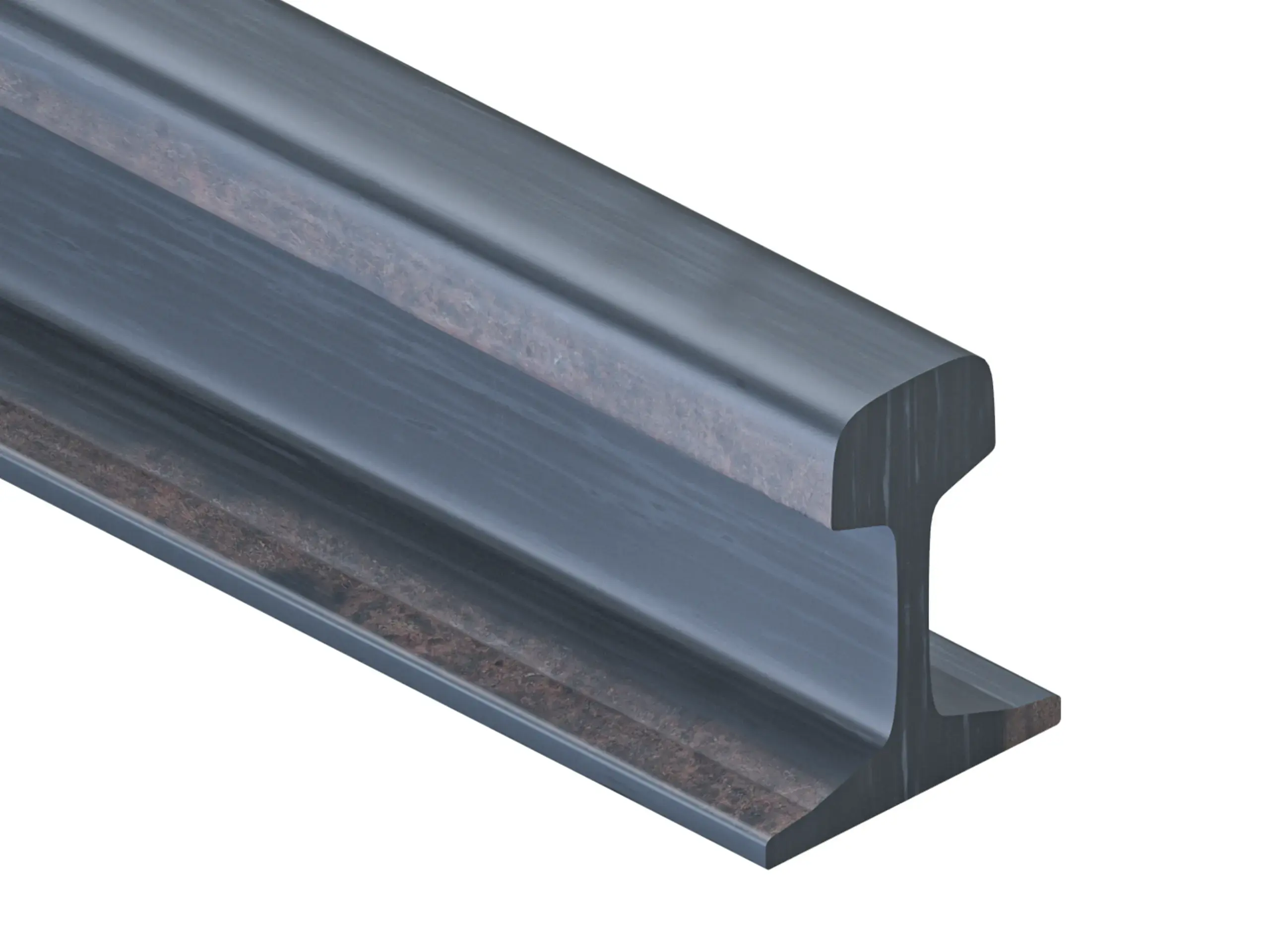

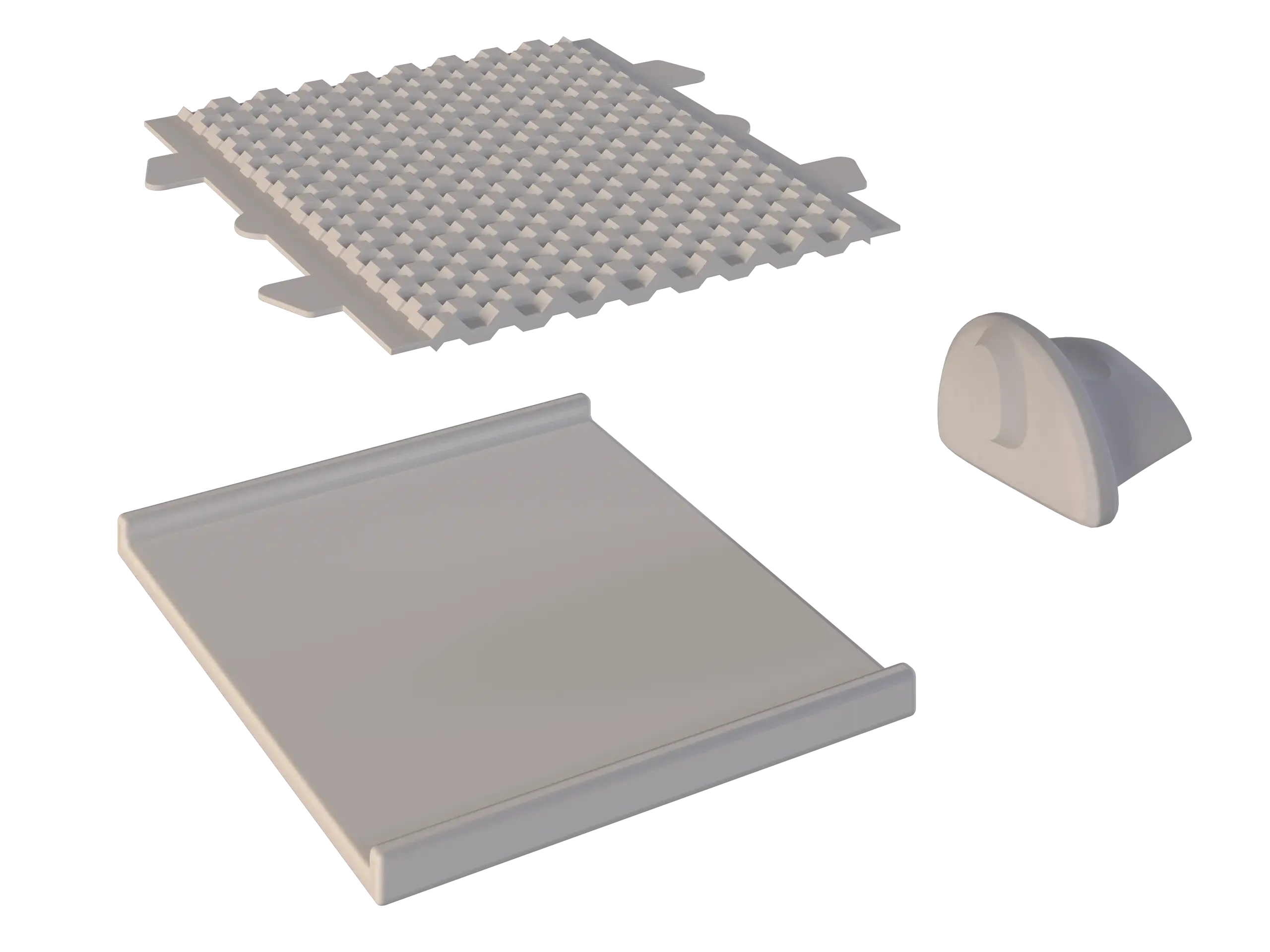

This is a rendered image. The real product will look different.

Select parameters

Type Please select an option to see price and add to cart

type of driling Please select an option to see price and add to cart

About delivery

- Personal pickup:

- If you pick up the rails with your own transport, please note that the rails are loaded from the top at our warehouse, and railway accessories are loaded with a forklift from the side.

- Oversized transport:

Only takes place during night hours (22:00-06:00).

- Transport by Moris:

Provide equipment and personnel for unloading the delivery.

Available delivery methods and costs will be displayed in the shopping cart during the order process.

Available delivery methods

Depending on the weight and length of the ordered products, we offer many convenient delivery methods.

We deliver orders starting from 1 item throughout Poland!

-

Self pick-up

You can collect the goods the next day after paying for the order.

-

Moris Transport

We will deliver the largest orders with our own transport.

-

Moris HDS

Delivery and crane unloading of products up to 7 m in length.

-

Rail transport

We will deliver rails with our own rolling stock. Pricing on individual request.

-

Parcel courier

Contact Customer Service if you would like to order a courier.

-

Pallet courier

We will soon enable the shipment of cut sections on pallets.

You will see the available delivery methods and costs in the cart while placing your order.

Flexible payment methods

Payment on Moris.eu is fast, convenient, and fully secure. We offer modern online payment methods such as Autopay, Apple Pay, Google Pay, BLIK, and card payments. For companies that prefer more traditional solutions, there is also the option of bank transfer based on a proforma invoice. We operate in accordance with international quality management standards – confirmed by the ISO 9001:2015 certificate.

-

Proforma invoice

Advance payment based on an issued invoice

-

BLIK

Mobile payment using a phone

-

Fast transfers

Support for the most popular banks in Poland

-

Digital wallets

Payment using Google Pay and Apple Pay

-

Credit/debit cards

Online payment by card: Visa, MasterCard, and others

Related Products

Description

Moris steel wholesaler offers a wide range of railroad shims - irreplaceable elements in railroad infrastructure. We offer ribbed shims in a variety of sizes, adapted to various technical requirements and operating loads. Thanks to our wide range of products and comprehensive technical support, customers can count on expert service and top-quality products that meet the most stringent industry standards.

Characteristics of ribbed washers

Ribbed washers, an integral part of railroad infrastructure, are designed to provide optimal distribution of rail pressure on the sleeper and protect bolted joints from loosening under vibration. Their distinctive feature is the presence of convex ribs that, together with a system of lugs, nut alloy bolts and spring rings, stabilize the position of the rail on the railroad sleepers, thereby improving the stability of the track structure. The material from which railroad sleepers are made (usually high-carbon steel or cast iron) undergoes a precise heat treatment process, which ensures their bending strength and abrasion resistance.

The manufacturing process of these key components begins with the de-rolling of the appropriate type of section depending on the type of shim. In the final stage, the ribbed shims undergo precision machining to ensure a perfect fit to the technical specifications of the track section.

Features and advantages of ribbed shims

Features of ribbed shims:

- High compressive and bending strength - by using high-carbon steel or cast iron, the shims can withstand heavy loads.

- Weather resistance - materials and heat treatment processes provide protection against corrosion.

- Precision manufacturing - ensures a perfect fit for different types of rails and sleepers.

Advantages of ribbed sleepers:

- Increased track stability - ribs improve pressure distribution, resulting in better stability.

- Long life - resistance to abrasion and corrosion extends service life.

- Reduced maintenance costs - stable track construction requires less frequent repairs.

- Versatility of application - fit many types of track and operating conditions.

Types of ribbed pads

We offer the following types of ribbed pads: BL3A, P24, P30, P39, PM 49 PRESS (49-2/160), PM 60, PM 60 PRESS (60-4/160), PS49A, PZ49A, PZ60A, PŻA 16, PŻA 16-20/160, PŻA16 (60-0-16/160), PŻA16/20 (60-0-20/160), PŻB 16A, PŻB16 (49-0-16), R65-2/160.

- PM49, PM49 PRASA (49-2/160), PM60, PM60 PRASA (60-4/160), P¯A16, P¯A16 (60-0-16/160), P¯B16A, P¯B16 (49-0-16), PS49A, BL3A: Standard types of pads, commonly used in tracks with standard loads, characterized by high compressive strength.

- PŻA 16-20/160, PŻA16/20 (60-0-20/160): Specialized pads designed for tracks with higher loads, providing better force distribution and increased track stability.

- PZ49A, PZ60A: Washers with increased resistance, recommended for installation in railroad turnouts.

- 65-2/160: Washers adapted to heavy duty conditions, mainly used on lines with heavy loads and traffic intensity.

- P24, P30, P39: Washers to be used for specific rail types

Each type of ribbed washer is designed for specific operating conditions and types of loads, allowing the track infrastructure to be precisely tailored to the needs of a specific section of the railroad line.

Applications of ribbed shims

Ribbed shims are a key component of railroad infrastructure, used to stabilize rails and distribute loads to sleepers. Different types of ribbed sleepers are designed and used depending on the specific requirements of a particular section of railroad line.

- PM49, PM49 PRASA (49-2/160), PM60, PM60 PRASA (60-4/160), P¯A16, P¯A16 (60-0-16/160), P¯B16A, P¯B16 (49-0-16), PS49A, BL3A: These types of rail pads are standardly used in conventional railroads. They are ideal for tracks with standard loads, ensuring even pressure distribution and track stability.

- PŻA 16-20/160, PŻA16/20 (60-0-20/160): These specialized rail pads are designed for use in areas with higher loads, such as high-speed lines or sections with heavy freight traffic. Their design allows for better force distribution and increased track stability.

- PZ49A, PZ60A: Shims with increased resistance, recommended for installation in railroad turnouts.

- R65-2/160: These rail pads are designed for use in the toughest operating conditions, such as heavy-duty lines, industrial lines or places with extreme weather conditions.

- P24, P30, P39: Shims to be used for specific rail types (S24, S30, S39

Each of these types of ribbed pads is designed and manufactured to maximize the safety, durability and efficiency of rail infrastructure, adapting to the specific conditions and requirements of each track section.

Advice for investors

- Analyze technical specifications - carefully study the technical specifications of railroad sleepers before making a purchase. Pay attention to dimensions, material, compressive strength, bending strength and weather resistance.

- Recognize operating conditions - determine the conditions under which the shims will be used, including load, intensity of rail traffic and climatic conditions. Select the type of rail pads that best suits these conditions.

- Total cost analysis - consider not only the purchase price of the rail pads, but also the costs associated with installation, maintenance and potential future replacement.

- Evaluating suppliers - choose suppliers with good reputations for technical support, fast delivery times and flexible terms of cooperation.

- Inventory planning - for large rail projects, consider establishing a strategic inventory of rail pads to prevent downtime in the event of unexpected failures or delivery delays.

Storage of ribbed shims

Proper storage of ribbed shims is key to maintaining their quality and functionality. Our recommendations:

- Protection from the weather - store rail pads in a dry and covered area to avoid corrosion and damage from moisture, rain, snow or extreme temperatures.

- Stacking on pallets or shelves - to prevent deformation, rail pads should be stacked on pallets or shelves rather than directly on the ground. Pallets also make transportation easier.

- Protect against mechanical damage - ensure adequate space between stacks of rail pads to avoid damage during handling. Use appropriate tools when doing so to avoid scratches or other damage.

- Regular condition checks - conduct regular inspections of stored rail pads to ensure that no damage or signs of corrosion have occurred.

Did you know

- Rail pads can be made from a variety of materials, including high-carbon steel, cast iron and even advanced composites depending on strength and weathering requirements.

- The first rail pads were simple metal plates. Over time, their shape has evolved to the current ribbed forms, which offer better stability and load distribution.

- Rail shims play a key role in maintaining track stability, which has a direct impact on the safety of rail travel.

- Some rail pads are specially designed for extreme conditions, such as extreme temperatures or areas with a high risk of mechanical damage.

Ribbed shims - why with us?

At Moris Steel Wholesale, we understand the importance of shims for rail infrastructure, so we offer a wide range of these components to meet the individual needs of each project. Our ribbed shims are characterized by high quality, durability and are available in a variety of specifications to precisely match specific technical requirements. Customers can count on professional service and technical advice, ensuring that the selected product fits perfectly into the technical and logistical parameters of the project. In addition, we offer flexible delivery options throughout Poland, ensuring fast and hassle-free order processing.