Spring ring

Order online or enquire through the Rail Sales Department.

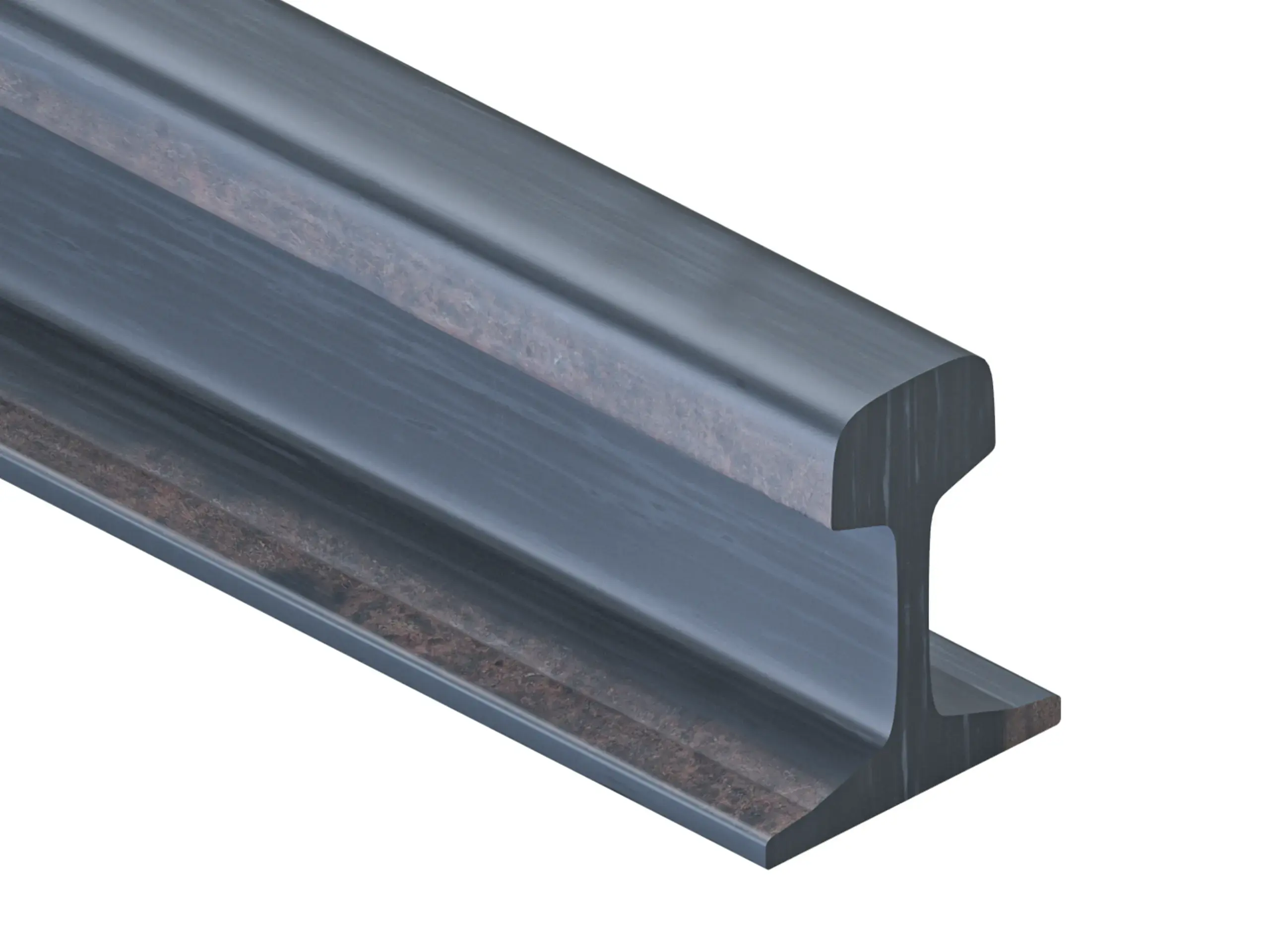

This is a rendered image. The real product will look different.

Select parameters

Type Please select an option to see price and add to cart

Product details

- Category 2Rail Accesories

About delivery

- Personal pickup:

- If you pick up the rails with your own transport, please note that the rails are loaded from the top at our warehouse, and railway accessories are loaded with a forklift from the side.

- Oversized transport:

Only takes place during night hours (22:00-06:00).

- Transport by Moris:

Provide equipment and personnel for unloading the delivery.

Available delivery methods and costs will be displayed in the shopping cart during the order process.

Available delivery methods

Depending on the weight and length of the ordered products, we offer many convenient delivery methods.

We deliver orders starting from 1 item throughout Poland!

-

Self pick-up

You can collect the goods the next day after paying for the order.

-

Moris Transport

We will deliver the largest orders with our own transport.

-

Moris HDS

Delivery and crane unloading of products up to 7 m in length.

-

Rail transport

We will deliver rails with our own rolling stock. Pricing on individual request.

-

Parcel courier

Contact Customer Service if you would like to order a courier.

-

Pallet courier

We will soon enable the shipment of cut sections on pallets.

You will see the available delivery methods and costs in the cart while placing your order.

Flexible payment methods

Payment on Moris.eu is fast, convenient, and fully secure. We offer modern online payment methods such as Autopay, Apple Pay, Google Pay, BLIK, and card payments. For companies that prefer more traditional solutions, there is also the option of bank transfer based on a proforma invoice. We operate in accordance with international quality management standards – confirmed by the ISO 9001:2015 certificate.

-

Proforma invoice

Advance payment based on an issued invoice

-

BLIK

Mobile payment using a phone

-

Fast transfers

Support for the most popular banks in Poland

-

Digital wallets

Payment using Google Pay and Apple Pay

-

Credit/debit cards

Online payment by card: Visa, MasterCard, and others

Related Products

Description

At Moris Steel Wholesale, we understand the important role that spring rings play in the rail industry, ensuring the reliability and durability of key track components. Our range of products includes a wide selection of spring rings to suit a variety of railroad structures, including the most demanding applications. We invite you to take a look at our comprehensive offer that meets the specific needs of the rail industry, providing solutions that are precise, reliable and available in a wide range of types and sizes.

Characteristics of spring rings

Spring rings are indispensable components in the rail sector, providing exceptional strength and flexibility, which is crucial in an area where safety and reliability are priorities. These specialized components are manufactured from high-strength materials such as spring steel, giving them excellent fatigue resistance and retaining their original mechanical properties even under extreme operating conditions.

The production of the spring ring involves advanced technological processes, including cold forming and heat treatment, which increases its strength and flexibility. Precision in the manufacturing process is key to ensuring that each spring ring meets stringent industry standards and customer expectations. This requires the use of controlled hardening and tempering processes, which further increases the rings' resistance to dynamic loads and environmental influences such as corrosion and temperature changes.

A characteristic of resilient rings is their ability to maintain stable and uniform pressure, which is crucial for maintaining the integrity of connections, as well as for ensuring the reliability and safety of rail infrastructure. Their design also allows for easy installation and replacement, which minimizes downtime in the operation and maintenance of rail infrastructure. In addition, the ability of the spring ring to absorb vibration and dampen noise contributes significantly to ride comfort and protect structural components from premature wear.

Spring rings are a key component in the rail industry, where their advanced mechanical properties and manufacturing process meet the requirements for durability, reliability and safety. Precision in manufacturing and the selection of suitable materials make them an indispensable solution, contributing to improved efficiency and stability in the rail sector.

Features and advantages of spring rings

Features of spring rings:

- Material strength - made of spring steel, providing high resistance to fatigue and damage.

- Flexibility - ability to retain original shape after deformation, crucial for maintaining the integrity of joints.

- Resistance to environmental conditions - high resistance to corrosion and temperature changes, thanks to heat treatment processes.

Advantages of spring rings:

- High durability - long-lasting preservation of mechanical properties, minimizing the need for frequent replacement.

- Protection of joints - stable and uniform pressure ensures protection of joints from loosening and vibration.

- Ease of installation - design allows for easy installation and replacement, reducing maintenance and repair time.

- Comfort and safety - vibration absorption and noise dampening contribute to safe and comfortable operation of railroad infrastructure.

Types of spring rings

We offer the following types of spring rings: Z1-28, Z2-25, Z2-28 and Z3-25.

Z1-28

- Features: High-strength ring optimized for heavy-duty applications.

- Advantages: Exceptional resistance to dynamic loads, ideal for high-demand applications.

- Disadvantages: Higher manufacturing cost due to specialized material and process requirements.

Z2-25

- Features: High flexibility and vibration absorption capacity, suitable for applications requiring flexible connection.

- Advantages: Excellent vibration damping, increasing comfort and durability of construction.

- Disadvantages: Limited resistance to very high loads compared to more durable models.

Z2-28

- Features: Balanced combination of strength and flexibility, suitable for a wide range of applications.

- Advantages: Versatile in application, good cushioning and strength properties.

- Disadvantages: May not meet the highest demands of specialized applications where maximum strength or flexibility is required.

Z3-25

- Features: Ring with high corrosion resistance, ideal for applications in extreme environmental conditions.

- Advantages: Exceptional resistance to external factors, including moisture, salt, temperature changes.

- Disadvantages: Higher costs associated with advanced materials and manufacturing technologies for corrosion resistance.

Application of spring rings

- Z1-28 resilient rings - this type of ring is ideal for applications in the most demanding parts of railroad infrastructure where loads are highest, such as track connections on bridges or in areas with heavy traffic. The exceptional strength of the Z1-28 spring ring makes it preferred where safety and reliability are crucial.

- Z2-25 spring rings - characterized by high flexibility, are used in areas where vibration absorption and noise dampening are a priority, for example, in track connections near residential areas. Their ability to reduce vibrations translates into increased driving comfort and extended infrastructure life.

- Z2-28 spring rings - are versatile rings that can be used in a variety of parts of the railroad system. Their balanced properties make them suitable for a wide range of applications - from track connections to fastening elements in railroad vehicles.

- Z3-25 spring rings - specially designed for applications in extreme environmental conditions, are used where corrosion resistance and variable weather conditions are essential. Ideal for areas exposed to salt, moisture or significant temperature changes.

Tips for investors

- Analyze operating conditions - before purchasing, carefully analyze the specific conditions in which the spring rings will be used. Parameters such as loads, atmospheric conditions and vibration levels are key to choosing the right type of ring.

- Long-term cost analysis - don't just go by the purchase price. It is worth considering the total cost of ownership, taking into account service life, frequency of replacement and maintenance costs.

- Verify certifications and standards - make sure that the spring rings you choose meet all applicable industry standards and have the necessary certifications as a guarantee of their quality and reliability.

Storage of spring rings

Proper storage of spring rings is key to maintaining their quality and functionality. Our recommendations:

- Stable environmental conditions - store rings in stable conditions, away from temperature extremes and moisture to prevent corrosion and material degradation.

- Clean and dry - make sure the storage area is clean and dry to avoid contaminants that can affect the mechanical properties of the rings.

- Proper packaging - use original or suitable replacement packaging to protect the rings from mechanical damage and contamination.

- Separation by type and size - store different types and sizes of rings separately to avoid confusion and facilitate quick access when needed.

- Systematic inventory control - regularly check the condition of rings and storage conditions to detect and prevent potential problems on an ongoing basis.

Did you know

- The materials used to manufacture spring rings have evolved over the years from simple carbon steels to advanced alloys, increasing their strength and fatigue resistance.

- Resilient rings are a key component in railroad safety systems, providing stability and durability to joints, which is essential to prevent accidents.

- Some types of rings are specially designed for extreme conditions, such as Z3-25, which exhibit exceptional corrosion resistance.

- By damping vibration and noise, spring rings have a significant impact on the comfort of train travel, minimizing noise and vibration transmitted to the vehicle structure.

- Resilient rings play an important role in maintaining the integrity of tracks, especially in heavy traffic areas where loads are significant and continuous.

Spring rings - why with us?

At Moris Steel Wholesale, we offer a wide range of spring rings to meet the specific requirements of our customers throughout the rail sector. Our commitment to providing professional customer service guarantees expert advice and technical support at every stage of cooperation. In addition, our understanding of the needs of the dynamic rail market translates into flexible delivery options that include a variety of transportation methods, available nationwide. By choosing Moris, you are choosing a reliable partner that combines quality, technical expertise and customer focus.