Clamps

Order online or enquire through the Rail Sales Department.

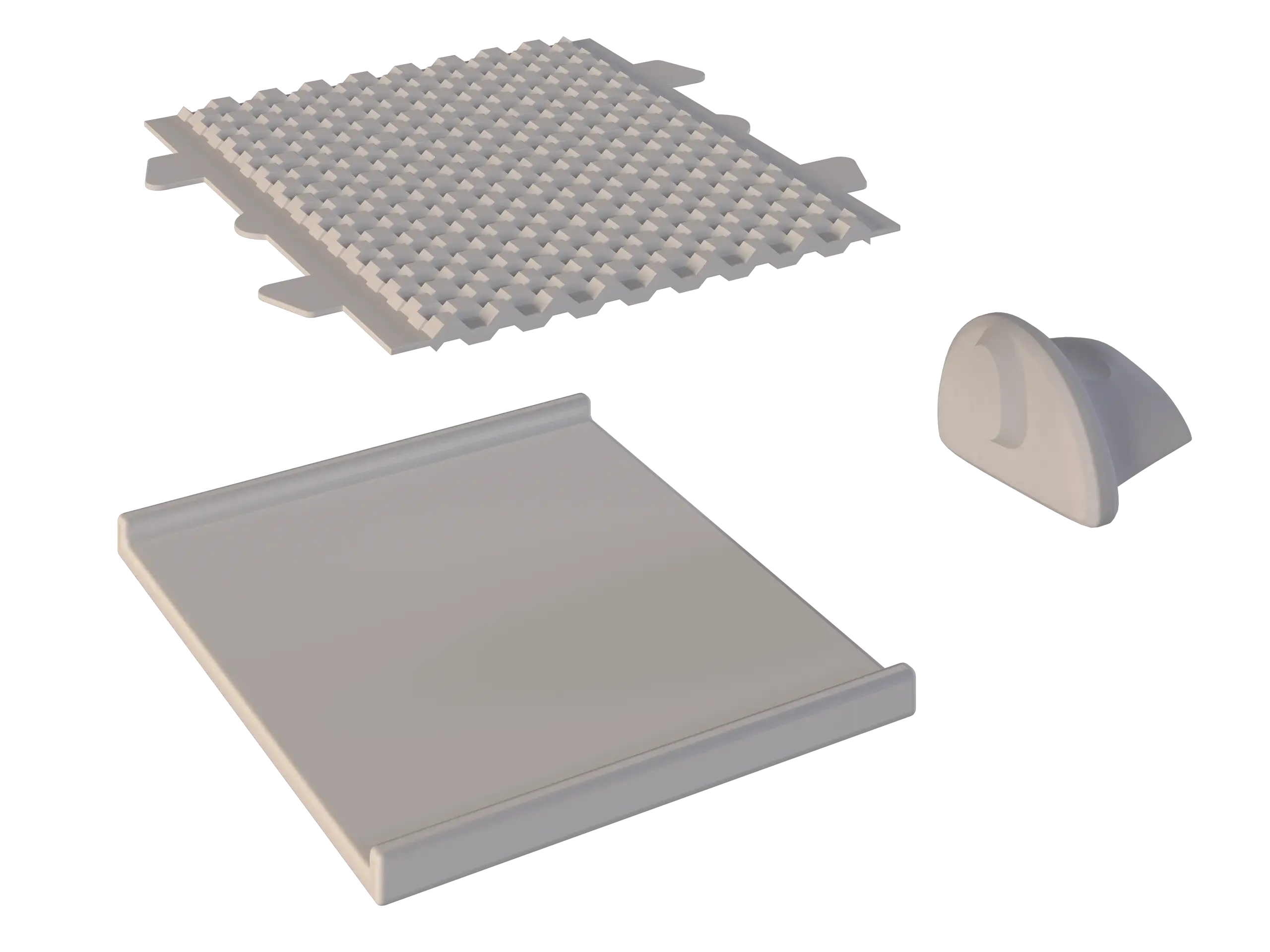

This is a rendered image. The real product will look different.

Select parameters

Type Please select an option to see price and add to cart

Product details

- Category 2Rail Accesories

About delivery

- Personal pickup:

- If you pick up the rails with your own transport, please note that the rails are loaded from the top at our warehouse, and railway accessories are loaded with a forklift from the side.

- Oversized transport:

Only takes place during night hours (22:00-06:00).

- Transport by Moris:

Provide equipment and personnel for unloading the delivery.

Available delivery methods and costs will be displayed in the shopping cart during the order process.

Available delivery methods

Depending on the weight and length of the ordered products, we offer many convenient delivery methods.

We deliver orders starting from 1 item throughout Poland!

-

Self pick-up

You can collect the goods the next day after paying for the order.

-

Moris Transport

We will deliver the largest orders with our own transport.

-

Moris HDS

Delivery and crane unloading of products up to 7 m in length.

-

Rail transport

We will deliver rails with our own rolling stock. Pricing on individual request.

-

Parcel courier

Contact Customer Service if you would like to order a courier.

-

Pallet courier

We will soon enable the shipment of cut sections on pallets.

You will see the available delivery methods and costs in the cart while placing your order.

Flexible payment methods

Payment on Moris.eu is fast, convenient, and fully secure. We offer modern online payment methods such as Autopay, Apple Pay, Google Pay, BLIK, and card payments. For companies that prefer more traditional solutions, there is also the option of bank transfer based on a proforma invoice. We operate in accordance with international quality management standards – confirmed by the ISO 9001:2015 certificate.

-

Proforma invoice

Advance payment based on an issued invoice

-

BLIK

Mobile payment using a phone

-

Fast transfers

Support for the most popular banks in Poland

-

Digital wallets

Payment using Google Pay and Apple Pay

-

Credit/debit cards

Online payment by card: Visa, MasterCard, and others

Related Products

Description

At Moris Steel Wholesale, we offer a wide range of railroad footings, which are an essential element in the rail industry to ensure the stability and safety of tracks. Our offer includes footings of various types, adapted to specific requirements and industry standards, which allows for optimal customization of each project. We invite you to take advantage of our offer, which guarantees not only a wide selection, but also expert advice and technical support.

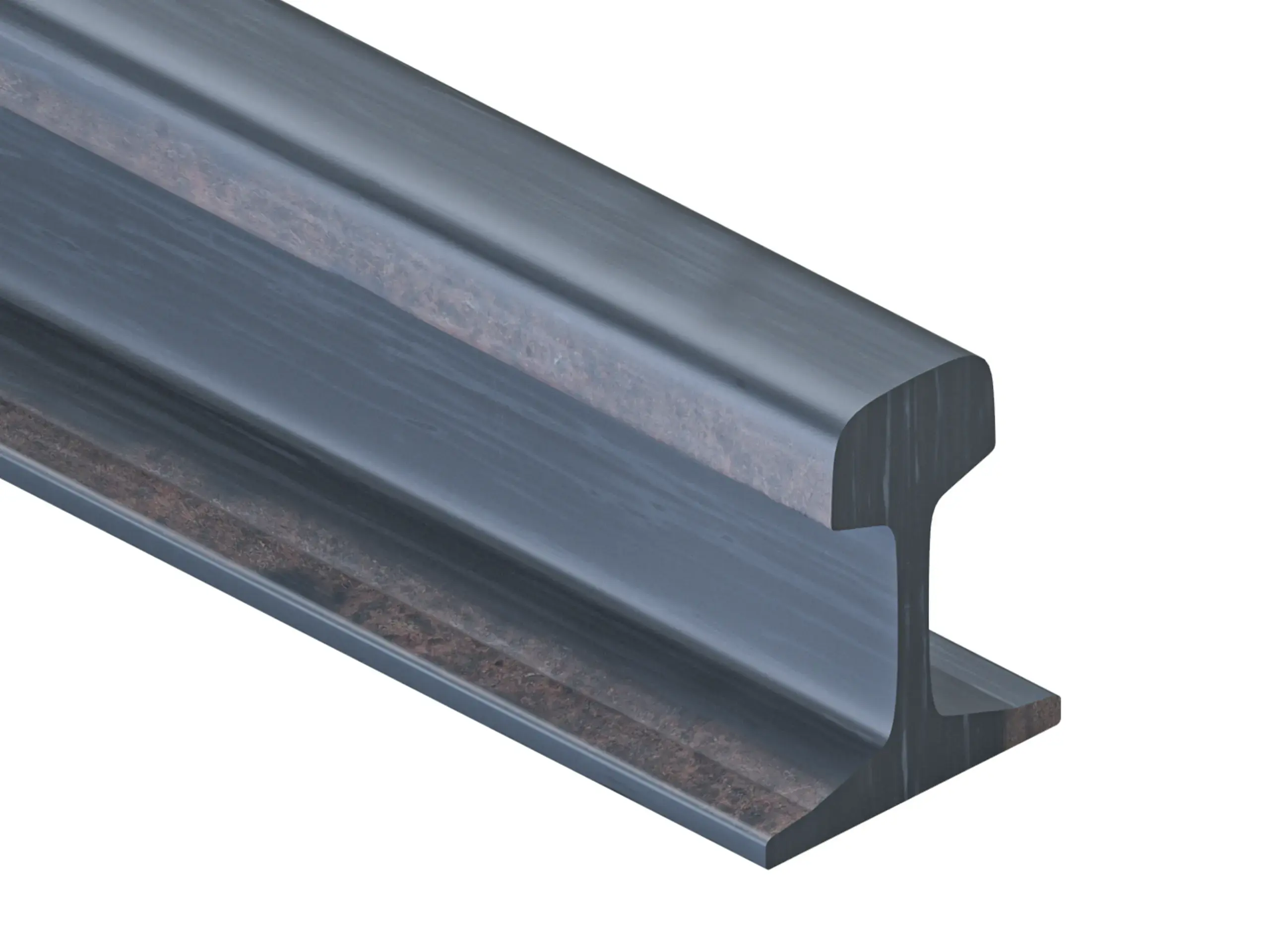

Characteristics of railroad footings

The rail foot is a key element in the construction of railroad tracks, performing an important function in ensuring stability and proper positioning of rails. This product is characterized by high precision manufacturing, which is necessary to maintain proper interlocking with other components of the track system. Railroad footings must meet strict standards and specifications to ensure the safety and continuity of rail traffic.

The production of railroad footings requires advanced metallurgical techniques and precise processes. The starting material is usually high-quality steel that is resistant to abrasion, impact and extreme temperatures. The manufacturing process begins with the initial forming of the material, which may include hot rolling, forging or casting, depending on the required specifications and properties of the final product.

The rolling, forging or casting process is followed by precision machining (cutting, hole-punching, milling), which allows accurate dimensions and shapes to be achieved in accordance with strict industry standards. Each rail foot is also subjected to detailed quality control.

A characteristic feature of rail footings is their ability to withstand extreme loads without deformation. In addition, they are designed to minimize friction and wear, resulting in longer track life and less frequent maintenance. Corrosion resistance is another important aspect, as rail footings are constantly exposed to adverse weather conditions.

Features and advantages of railroad footings

Features of railroad footings:

- High durability - the materials used in production provide high resistance to mechanical loads and abrasion.

- Precise dimensioning - dimensional accuracy for perfect fit to rails and other track components.

- Resistance to atmospheric conditions - materials resistant to corrosion and temperature changes, which ensures long-term use.

Advantages of railroad footings:

- Safety - they increase track stability, minimizing the risk of accidents.

- Durability - long life due to the strength of materials and resistance to damage.

- Savings - reduce track maintenance costs due to less wear and less frequent replacements.

- Versatility - can be used in various operating conditions and with different types of rails.

Types of rail clamps

Our offer includes rail clamps of the following types: ŁP2, ŁP2 (ZS4/65), ŁP3, ŁP5 and Łpa2.

ŁP2

Features:

- Standard railroad bribe, widely used.

- Designed to work in standard conditions.

Advantages:

- High strength.

Disadvantages:

- Less specialization compared to other types of bribes.

ŁP3

Features:

- A pawpaw designed for use in more demanding conditions, with better technical performance.

Advantages:

- Improved load resistance and better resistance to variable weather conditions.

Disadvantages:

- Higher cost compared to ŁP2.

ŁP5

Features:

- A version of the pawl designed for use in the toughest conditions and under the heaviest loads.

Advantages:

- Superior strength and resistance to damage and extreme conditions.

Disadvantages:

- Higher cost and possible need for specialized installation.

Lpa2

Features:

- A bench with increased flexibility, designed for special applications where greater adaptation to track traffic is required.

Advantages:

- Better adaptation to track dynamics, reduction of stresses in rails.

Disadvantages:

- Specialized application.

Application of railroad footings

- ŁP2 railroad foot ing - a universal type of footing, widely used in standard track construction. Due to its robustness and reliability, it is ideally suited for use in conventional railroad tracks, where operating conditions do not require special solutions. The ŁP2 is chosen for its versatility and ease of installation and maintenance.

- ŁP2 railroad footing (ZS4/65) - this type of footing is an adaptation of the standard ŁP2 model, designed to increase strength and stability in more demanding operating conditions. Its use is preferred on sections of track with heavier traffic or where there are higher loads, such as on main railroad lines or in areas of heavy freight traffic.

- ŁP3 railroad footing - designed for use in more demanding environments where standard footings may not meet expected requirements. With improved load resistance and better weather resistance, ŁP3 is often used in areas exposed to extreme conditions, such as bridges, overpasses or sections of track with steep gradients.

- ŁP5 railroad footing - the highest level of strength and resistance to damage. The preferred choice for the most demanding track applications. Used on sections of track where maximum stability and safety are required, such as on high-speed lines, at complex railroad junctions or where extreme dynamic loads occur.

- Łpa2 railroad footing - is used in specific conditions where greater flexibility of the track structure is required. Thanks to its ability to adapt to dynamic loads and movements of the track, Lpa2 is often used in places where conventional footings might not provide sufficient stability or durability, such as on large-radius curves, at level crossings, or where the track is exposed to frequent load changes.

Tips for investors

- Careful analysis of requirements - before purchasing, determine the needs of your project in detail, taking into account the type of track, traffic volume and environmental conditions. The selection of the right type of railroad footing should be dictated by specific technical requirements.

- Check certifications and standards - make sure that the railroad footings you choose meet all applicable industry standards and norms. Quality certifications are a guarantee of product durability, strength and safety.

- Analyze operating conditions - consider the conditions in which the rail footings will be operated. Products intended for use in extreme weather conditions or on heavily loaded railroads should feature increased resistance to abrasion and corrosion.

- Total cost analysis - consider not only the purchase price, but also the cost of installation, maintenance and potential replacement. An investment in higher quality railroad footings may be more economical in the long run due to less frequent replacement and lower maintenance costs.

- Plan logistics - arrange for efficient transportation and storage of rail footings to ensure they are protected from damage and corrosion prior to installation.

- Maintain inventory - consider purchasing additional rail footings for the future to ensure easy replacement or expansion of tracks without having to fit new batches of products into existing infrastructure.

Storage of railroad footings

Proper storage of railroad footings is key to maintaining their quality and functionality. Our recommendations:

- Avoiding contact with the ground - railroad footings should be stored on racks or pallets to avoid direct contact with the ground and potential damage.

- Protection from mechanical damage - store rail roundups in a way that protects them from impacts or other mechanical damage.

- Systematic stack ing - rail roundups should be stacked systematically in such a way that each piece can be easily accessed without moving other items.

- Ensure good organization - label and catalog railroad footings in a way that allows easy identification and access to individual types and lots.

Did you know

- Railroad footings were used as early as the first steam railroads, where they performed a key function in maintaining track stability.

- Today's railroad footings are manufactured from advanced steel alloys specifically designed to withstand extreme loads and weather conditions.

- The shape of rail footings is the result of years of research and testing to minimize friction and wear on the rails and the footing itself.

- Properly designed and installed rail footings significantly contribute to rail safety, reducing the risk of train derailments.

Railroad footings - why with us?

At Moris Steel Wholesale, we offer a wide range of railroad footings that meet the highest industry standards, tailored to the various needs and technical specifications of our customers.

Our team consists of experienced specialists who provide professional service and expert technical advice, ensuring that each purchase is well thought out and tailored to individual project requirements.

Thanks to our efficient logistics, we are able to offer flexible and timely delivery options for railroad footings throughout Poland.

When you choose Moris, you are choosing a reliable partner in the rail industry.