Tonque rails

Order online or enquire through the Rail Sales Department.

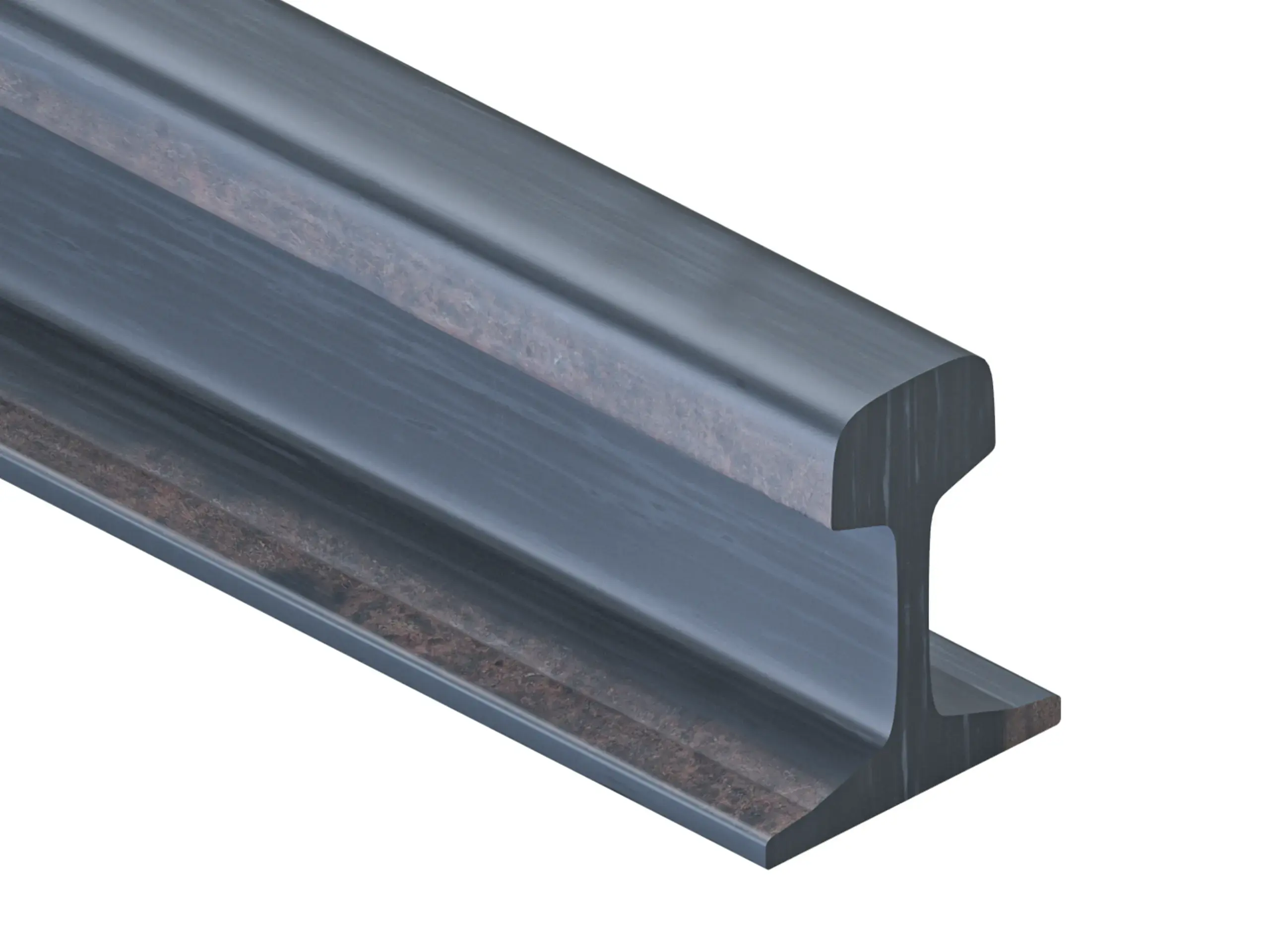

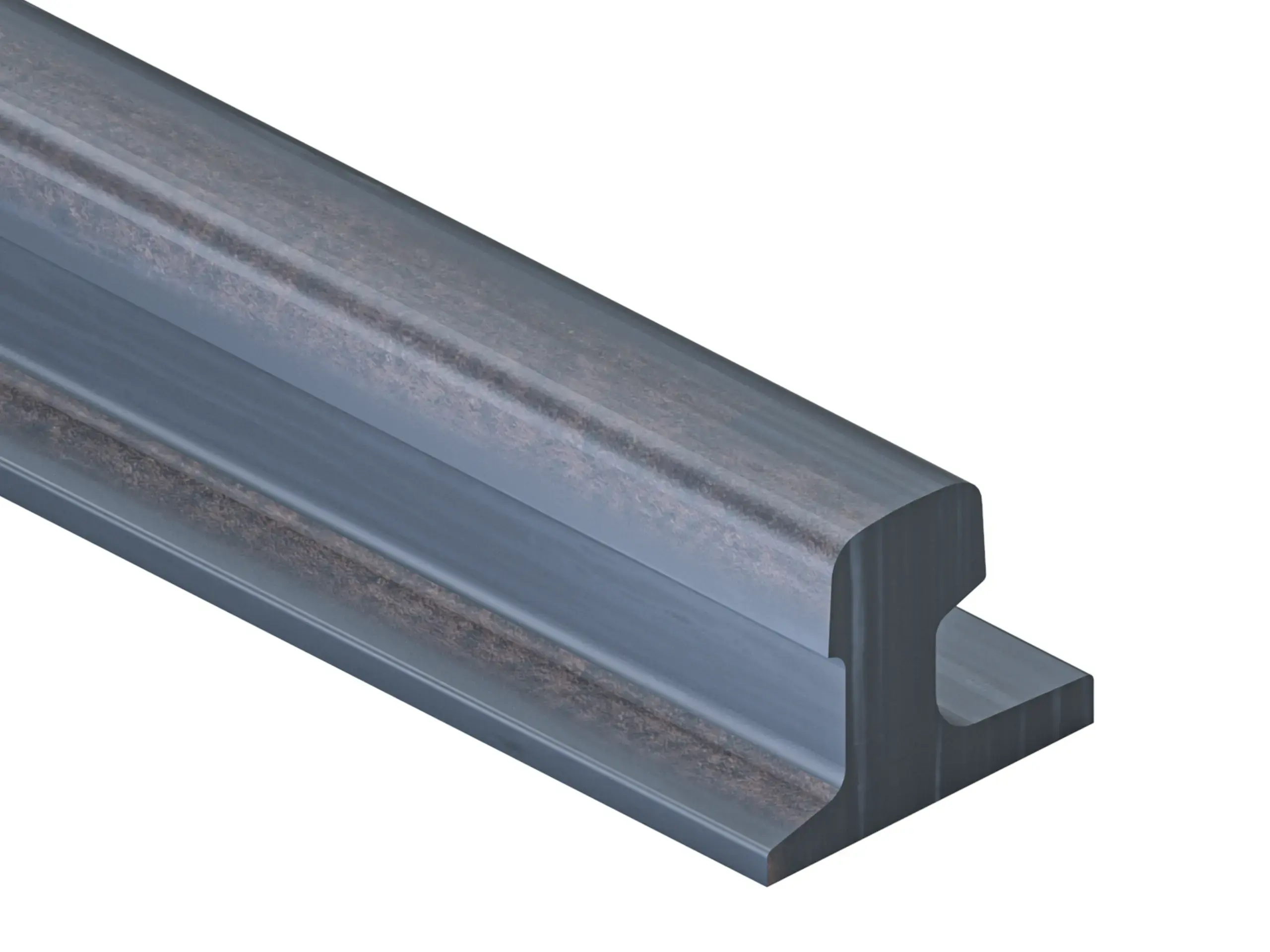

This is a rendered image. The real product will look different.

Select parameters

Rail profile Please select an option to see price and add to cart

Steel grade

Length - L [mm] Please select an option to see price and add to cart

About delivery

- Delivery of long rails (120-360m) by railcar:

The price includes a shunting locomotive for unloading the rails and coordination of unloading work by two MORIS employees, using a railcar unloading machine.

The buyer shall provide three workers for simple unloading work and a Train Manager.

The buyer shall ensure the traction power is switched off during unloading.

- Personal pickup:

If you pick up the rails with your own transport, please note that the rails are loaded from the top at our warehouse, and railway accessories are loaded with a forklift from the side.

- Oversized transport:

Only takes place during night hours (22:00-06:00).

- Transport by Moris:

Provide equipment and personnel for unloading the delivery.

Available delivery methods and costs will be displayed in the shopping cart during the order process.

Available delivery methods

Depending on the weight and length of the ordered products, we offer many convenient delivery methods.

We deliver orders starting from 1 item throughout Poland!

-

Self pick-up

You can collect the goods the next day after paying for the order.

-

Moris Transport

We will deliver the largest orders with our own transport.

-

Moris HDS

Delivery and crane unloading of products up to 7 m in length.

-

Rail transport

We will deliver rails with our own rolling stock. Pricing on individual request.

-

Parcel courier

Contact Customer Service if you would like to order a courier.

-

Pallet courier

We will soon enable the shipment of cut sections on pallets.

You will see the available delivery methods and costs in the cart while placing your order.

Flexible payment methods

Payment on Moris.eu is fast, convenient, and fully secure. We offer modern online payment methods such as Autopay, Apple Pay, Google Pay, BLIK, and card payments. For companies that prefer more traditional solutions, there is also the option of bank transfer based on a proforma invoice. We operate in accordance with international quality management standards – confirmed by the ISO 9001:2015 certificate.

-

Proforma invoice

Advance payment based on an issued invoice

-

BLIK

Mobile payment using a phone

-

Fast transfers

Support for the most popular banks in Poland

-

Digital wallets

Payment using Google Pay and Apple Pay

-

Credit/debit cards

Online payment by card: Visa, MasterCard, and others

Related Products

Description

The needle sections available at Moris Wholesale are a unique solution for companies looking for the highest quality structural components. Our range includes a wide assortment of needle sections, providing a variety of types and lengths to suit the specific requirements of any project.

Made from precisely selected materials, our needle sections are characterized by high strength and durability, making them an ideal choice for advanced engineering applications.

Characteristics of needle sections

Needle sections are a specific type of steel products that are characterized by their unique profile and properties. The production of needle sections involves rolling the steel in a high-temperature process that provides them with the necessary hardness and strength.

These sections are characterized by a profile that is narrower and longer than standard sections, with dimensions tailored to specific technical requirements. This design peculiarity gives them exceptional efficiency in structures that require special precision like railroad turnouts.

Needle sections can be produced in a variety of sizes and lengths, depending on individual customer needs, which emphasizes their versatility. In the production process, it is also important to maintain the appropriate chemical properties of the steel, which guarantees optimal product performance in various operating environments.

Features and advantages of needle sections

- Characterized by a narrow and long profile.

- Made of high-quality steel, which provides a solid base for further processing (forging, heat treatment or machining). Such processing improves their physical and mechanical properties.

- They provide a solid base for creating structures of high strength and durability like railroad turnouts.

Spire sections

We offer needle sections with profiles 49E1A3, 60E1A1 and 60E1A6, which can be used for the construction of various types of railroad turnouts.

- Standard turnouts - 49E1A3 and 60E1A1 profiles are often used in standard railroad turnouts, which are commonly used in a typical railroad network. These turnouts are used on major railroads where high strength and reliability are required.

- Turnouts for heavy loads - the 60E1A6 profile, due to its higher strength, is ideal for turnouts designed to handle heavy loads, such as those used in freight transportation, on industrial lines, or in areas with heavy train traffic.

- High-speed turnouts - the 60E1A1 profile can be used in turnouts designed for high-speed lines, where exceptional strength and stability are required to cope with higher train speeds.

- Specialized turnouts - Profiles 49E1A3 and 60E1A6 can be used in specialized turnouts, such as those used in locations with special technical requirements, for example, in mountainous regions, on railroad bridges or in other difficult operating conditions.

- Urban and streetcar turnouts - the 49E1A3 profile, due to its versatility, can also be used in urban turnouts, including streetcar and light rail systems, where good adaptation to the urban landscape and lower loads are required.

Steel grades

We offer needle sections made of R260 and R350HT steel. Due to their different properties, they are used in different types of railroad turnouts.

R260 steel

- Standard turnouts - R260 steel is suitable for standard railroad turnouts used in a typical railroad network, especially on lines with lower loads.

- Urban and streetcar turnouts - ideal for urban rail systems, including streetcars and light rail lines, where loads are moderate and material flexibility is important.

R350HT steel

- Turnouts for heavy loads - R350HT steel, which is a higher grade in terms of strength, is ideal for railroad turnouts designed to handle heavy loads, such as in freight transportation or industrial lines.

- High-speed turnouts - due to its higher strength, R350HT steel is also suitable for turnouts on high-speed lines, where strength and stability are key.

- Turnouts in harsh environments - R350HT steel is suitable for areas with harsh operating conditions, including mountainous regions, railroad bridges and areas with harsh weather conditions, where higher resistance to corrosion and wear is required.

The selection of the appropriate steel grade for needle sections depends on the specific requirements of the railroad turnout, including loads, rail traffic speeds and weather conditions. R260 steel is more versatile and suitable for standard applications, while R350HT steel is preferred for more demanding turnout designs.

Applications for needle sections

- Spire sections are used as a basic component in the construction of railroad turnouts. These turnouts allow trains to change tracks, allowing vehicles to be diverted to different tracks at branch lines or stations.

- One of the main uses of needle sections in turnouts is to form crossings, which are key components that allow trains to pass from one track to another.

- Needle sections are manufactured in a variety of sizes and profiles, allowing them to be used in turnouts with different parameters.

- Due to the possibility of precise processing, needle sections can be adapted to specific technical requirements, which is particularly important in turnouts with unusual parameters or specialized applications.

- Needle sections ensure long-term, reliable operation of turnouts, minimizing the need for frequent repairs or replacements, which is crucial from the point of view of economics and efficiency of railroad infrastructure management.

Advice for investors

- Evaluate technical specifications - make sure that the technical specifications of the needle sections are in line with the requirements of your project. Check parameters such as dimensions, tolerances, chemical composition of the steel and its mechanical properties.

- Selecting the right steel grade - choose a steel grade suitable for the operating conditions of the sections. Consider aspects such as corrosion resistance, mechanical strength and flexibility.

- Analyze suppliers - choose suppliers with a good reputation in the market that offer not only quality products, but also technical support and various delivery options.

- Total cost analysis - don't just look at the purchase price. Consider the total cost, including transportation, installation and possible repairs.

- Evaluate availability and logistics - make sure that the chosen supplier is able to deliver the sections in the right quantities and on schedule, minimizing the risk of project delays.

Storage of spire sections

Proper storage of needle sections is crucial to maintaining their quality and functionality. Our recommendations:

- Horizontal stacking - needle sections should be stored horizontally to prevent bending and structural damage.

- Supports - use properly spaced supports to ensure stability and even weight distribution.

- Roofing - store sections in a dry, covered area to protect them from the weather.

- Accessibility and storage - arrange sections in a way that allows easy access and identification, while maintaining safe handling space.

Did you know

- Spire sections are known for their durability, which is key in rail infrastructure where minimal maintenance is required.

- The specific shape of spire sections is designed to optimize the weight-to-strength ratio, which is critical in engineering projects.

Spire sections - why with us?

At Moris Steel Wholesale, we offer a wide selection of spire sections that meet the highest standards of quality and strength, perfectly meeting the needs of advanced railroad projects. Our experience in the industry guarantees professional service and expert technical advice, helping our customers to choose the best solutions. In addition, we provide flexible and efficient delivery options throughout Poland, adapting to the individual requirements and schedules of our partners.