Crane roadways rails

Order online or enquire through the Rail Sales Department.

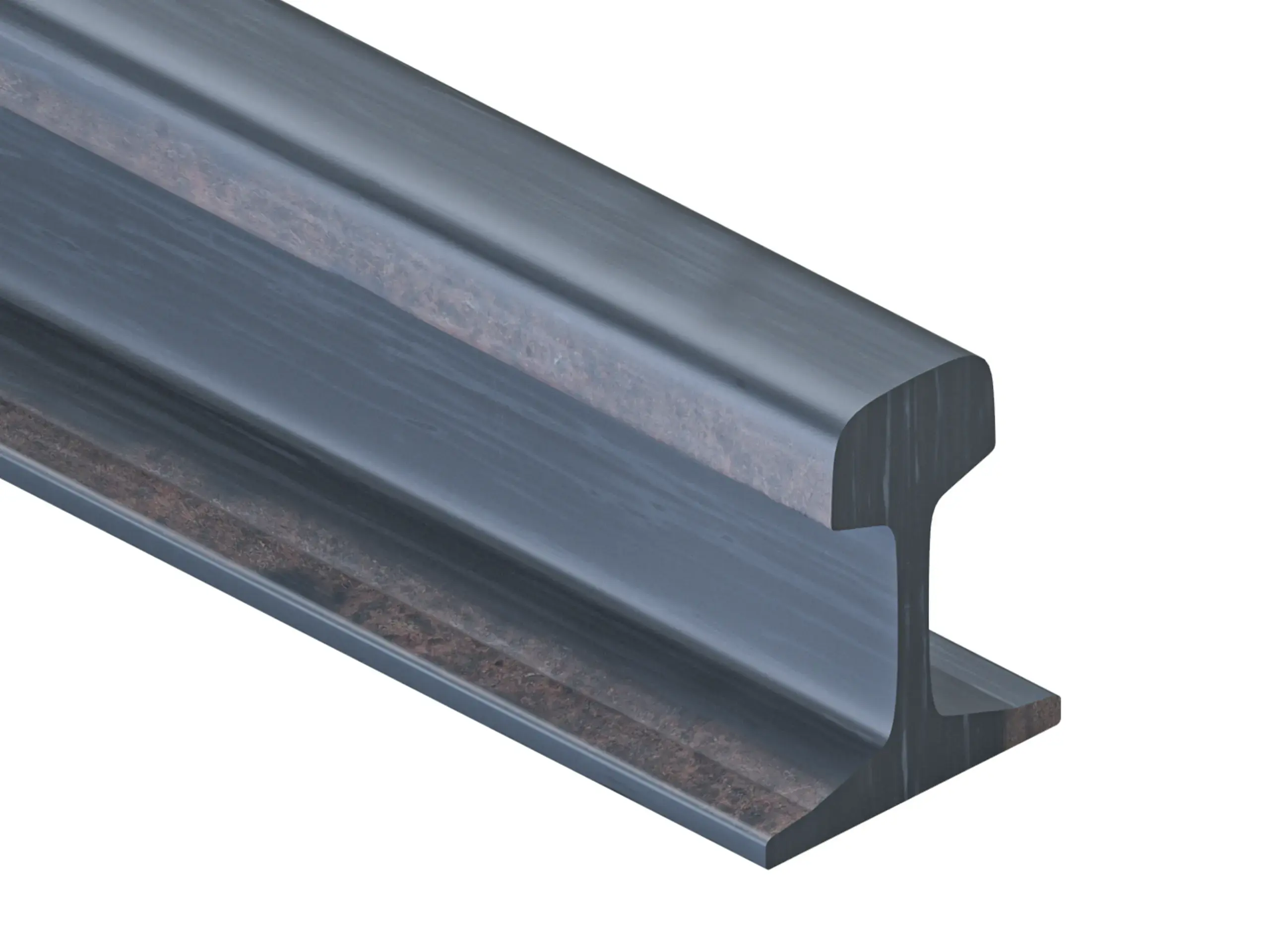

This is a rendered image. The real product will look different.

Select parameters

Rail profile Please select an option to see price and add to cart

Steel grade

Length - L [mm] Please select an option to see price and add to cart

About delivery

- Personal pickup:

- If you pick up the rails with your own transport, please note that the rails are loaded from the top at our warehouse, and railway accessories are loaded with a forklift from the side.

- Oversized transport:

Only takes place during night hours (22:00-06:00).

- Transport by Moris:

Provide equipment and personnel for unloading the delivery.

Available delivery methods and costs will be displayed in the shopping cart during the order process.

Available delivery methods

Depending on the weight and length of the ordered products, we offer many convenient delivery methods.

We deliver orders starting from 1 item throughout Poland!

-

Self pick-up

You can collect the goods the next day after paying for the order.

-

Moris Transport

We will deliver the largest orders with our own transport.

-

Moris HDS

Delivery and crane unloading of products up to 7 m in length.

-

Rail transport

We will deliver rails with our own rolling stock. Pricing on individual request.

-

Parcel courier

Contact Customer Service if you would like to order a courier.

-

Pallet courier

We will soon enable the shipment of cut sections on pallets.

You will see the available delivery methods and costs in the cart while placing your order.

Flexible payment methods

Payment on Moris.eu is fast, convenient, and fully secure. We offer modern online payment methods such as Autopay, Apple Pay, Google Pay, BLIK, and card payments. For companies that prefer more traditional solutions, there is also the option of bank transfer based on a proforma invoice. We operate in accordance with international quality management standards – confirmed by the ISO 9001:2015 certificate.

-

Proforma invoice

Advance payment based on an issued invoice

-

BLIK

Mobile payment using a phone

-

Fast transfers

Support for the most popular banks in Poland

-

Digital wallets

Payment using Google Pay and Apple Pay

-

Credit/debit cards

Online payment by card: Visa, MasterCard, and others

Related Products

Description

Our product range includes a variety of crane rail types and lengths, providing the flexibility to choose the right product for the specific needs of your projects. The crane rails available at Moris are characterized by precision manufacturing from high-quality steel, guaranteeing reliability in the most demanding operating conditions. We provide our customers with comprehensive technical support and expert advice in selecting the ideal solutions, tailored to individual requirements and technical specifications.

Characteristics of crane rails

Crane rails are a key component of the infrastructure of many crane systems, characterized by high resistance to static and dynamic loads. These rails are manufactured from high-quality steel and exhibit bending resistance and wear resistance, which are key to maintaining the safety and efficiency of crane operations.

The manufacturing process of crane rails begins with the selection of the right grade of steel, which is critical to the properties of the final product. The steel is then subjected to a hot-rolling process to achieve the required shapes and dimensions. After rolling, the rails are cooled in a controlled manner, ensuring that their mechanical properties, such as hardness and strength, are optimized. The next stage is machining, which includes cutting to size (including cutting at an angle).

Crane rails are also characterized by their profile, designed to allow the crane wheel to move smoothly along the rail, minimizing the risk of derailment. The rails are also designed to withstand a wide variety of weather conditions, especially in outdoor environments, requiring appropriate protective coatings and maintenance methods.

Features and advantages of crane rails

Features of crane rails:

- Made of high-quality steel, which provides high strength to withstand loads.

- Designed for long-term use with minimal wear.

- Dimensionally accurate for easy installation and compatibility with various crane systems.

- Can be used in a variety of environmental conditions through the use of protective coatings.

- High stability and operational safety.

Advantages of crane rails:

- Long service life even in intensive use.

- Wear resistance translates into less maintenance and repair.

- Can be used in a variety of crane systems.

Crane rail profiles

We offer crane rails with profiles A45, A55, A65/SD65, A75/SD75, A100/SD100, A120 and A150. These crane rail profiles mainly differ in dimensions and strength, which determines their use in different types of cranes and working environments.

- A45 and A55 - are relatively smaller, ideal for lighter structures. They are characterized by lower strength, but are more economical.

- A65/SD65 and A75/SD75 - more versatile, increased strength makes them suitable for medium loads.

- A100/SD100 and A120 - designed for heavier duty, provide greater strength and stability.

- A150 - the largest and most robust profiles, designed for the heaviest industrial applications.

Features:

- Each profile has exact dimensions, ensuring compatibility and ease of installation.

- Various load strength levels to suit specific needs.

Advantages:

- Wide selection of profiles to suit specific project requirements.

- Ability to select the most appropriately priced profile for a given application.

Disadvantages:

- Larger profiles can be more difficult to install and require more space.

- Larger and more robust profiles are more expensive, which can affect the overall cost of a project.

Steel grades

Steel 700 (690 MPa):

Features:

- Characterized by high loading strength and good flexibility.

- Advantages:

- Good wear resistance, which extends the life of rails.

- Better flexibility compared to higher hardness steels, which minimizes the risk of cracking.

Disadvantages:

- Lower hardness than 900 steel, which can lead to faster wear.

Steel 900 (880 MPa):

Features:

- Has higher hardness and wear resistance than 700 steel.

Advantages:

- Increased wear resistance, especially in high-traffic areas.

- Longer service life in harsh operating conditions.

Disadvantages:

- Higher hardness can lead to greater brittleness, increasing the risk of cracking.

- Higher production cost compared to 700 steel.

Crane rail applications

A45:

- Mainly used in lightweight lifting systems such as small freight cranes and workshop cranes.

A55:

- Used in medium lift systems such as cranes in residential buildings and small shopping centers.

A65/SD65:

- Ideal for medium-sized industrial cranes, used in warehouses and small manufacturing plants.

A75/SD75:

- Used in larger industrial crane systems, such as cranes in large warehouses and manufacturing plants.

A100/SD100:

- Used in very heavy industrial structures, including large manufacturing plants and construction projects.

A120:

- They are used in large engineering and construction projects where very high strength and stability are required.

A150:

- Used in the toughest industrial conditions, including large-scale construction and engineering projects requiring superior strength and stability.

Advice for investors

- Determine requirements - Define the exact load requirements and operating conditions for the crane.

- Select a steel grade - Choose a steel grade suitable for operating conditions (e.g., corrosion-resistant steel for outdoor structures).

- Profile selection - Decide on a suitable rail profile depending on the strength requirements and crane type.

- Quality control - make sure the rails are certified and meet appropriate quality standards.

- Supplier analysis - choose a reliable supplier with good references and industry experience.

- Compatibility assurance - check that the selected rails are compatible with the rest of the crane system.

- Availability analysis - pay attention to rail availability and delivery dates to avoid project delays.

- Evaluate total cost - consider not only the purchase price, but also the cost of installation, maintenance and possible repairs.

Storage of crane rails

Proper storage of crane rails is key to maintaining their quality and functionality. Our recommendations:

- Dry storage - provide a dry and well-ventilated space for storing rails to prevent corrosion.

- Protection from damage - use protective pads to avoid direct contact of rails with the ground and potential damage.

- Laying horizontally - rails should be laid horizontally on stable supports evenly spaced along their length.

- Tipping protection - make sure rails are properly secured to prevent accidental tipping.

- Marking and identification - clearly mark the rails for easy identification and quick access to the desired profiles.

- Access to rails - ensure easy access to rails to avoid unnecessary movement, which can lead to damage.

- Regular condition checks - regularly check the condition of stored rails to quickly detect and prevent potential problems.

Did you know

- Crane rails are usually made of steel with special properties, such as increased resistance to bending and abrasion.

- The geometric precision of the rails is crucial to ensure smooth crane movement and minimize the risk of failure.

- Crane rails have a much longer service life than many other crane components, which reduces operating costs.

- There are different rail profiles, such as A45 or A150, each designed for specific loads and applications.

- The manufacturing process of crane rails combines advanced metallurgical technology and precision machining.

Crane rails - why from us?

When you choose crane rails from Moris online steel wholesaler, you are sure to receive products of the highest quality, tailored to your individual needs and technical requirements. We offer a wide selection of crane rails with different profiles, while providing professional service and technical advice, which is key to choosing the optimal solution. In addition, our wholesaler guarantees a variety of delivery options, enabling quick and efficient delivery of products directly to the site of your investment.

FAQ

What are crane rails made of?

Crane rails are mainly made from carbon steel, which is properly hardened and heat-treated to achieve the desired mechanical properties. The choice of a particular type of steel depends on the requirements for strength, hardness, flexibility and resistance to wear and corrosion.

The two basic types of steel that are often used to manufacture crane rails are:

1.700(690MPa) steel - this is the general name for a fairly high strength steel that is often used in crane structures for its strength and durability.

2.steel 900(880 MPa) - is an even higher strength steel that is used in more demanding applications where additional strength and resistance to high loads are needed.

In addition, to improve durability and corrosion resistance, crane rails can be subjected to processes such as galvanizing or anti-corrosion painting. Surface treatment of such rails is crucial, especially if they are to be used in high humidity environments or where they may be exposed to aggressive chemicals.