history of steel making

Steel can undoubtedly be called one of the most famous, but also the most important alloys in the history of mankind. However, in order to better understand its properties and contribution to mankind, it is worth knowing its history. So it's time for a short trip back in time.

The history of steel goes back to remote antiquity. At that time it was discovered that as little as 1.5% admixture of carbon added to iron makes the resulting alloy much harder and more durable. The first evidence of its production, mainly in terms of small arms, dates back to the 12th century BC. Steel was produced in ancient Sparta around the 7th century BC, and later in the Roman Empire. Parallel to Europe, its production was also developed in India, China and the Middle East.

One of the most famous and prized was Damascus cru cible steel, used around the 11th century AD to make sword blades. It was produced in Damascus from ingots of wootz steel (developed around the 3rd century BC), imported from India and Sri Lanka. Steel, in its various varieties and degrees of purity, was for centuries a valued material mainly in the manufacture of armaments, or specialized tools. Its manufacture, however, was linked to extensive logging, since in addition to iron ore, charcoal was needed - and in large quantities - to make it.

Evolution

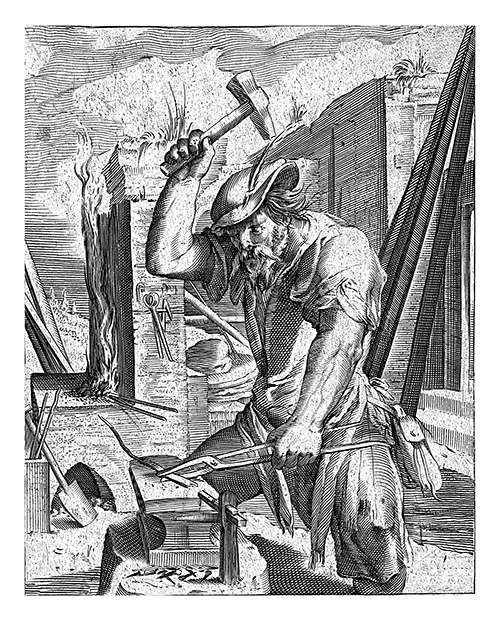

The first step to optimize the steelmaking process was its smelting from cast iron, the so-called pig iron. This method was developed in Styria, located in what is now Austria. However, the pig iron produced in this way had - for steel - too high a carbon content (far above the required 2%). Therefore, the pig iron had to be melted with a piece of soft iron. On top of that, it contained many undesirable impurities, such as sulfur, phosphorus, nitrogen and oxygen, which adversely affected its final quality. The solution to this problem turned out to be the process of freshing, that is, supplying the alloy with a large amount of air to burn off any impurities.

In the 14th century, the first frying furnaces appear. The frying process consisted of freshing pig iron based on special bellows supplying a large amount of air to the furnace. This resulted in a fairly effective afterburning of unwanted admixtures in the pig iron.

Another important breakthrough came in 1702, when coke is used instead of charcoal in the pig iron smelting process. This contributes to a significant reduction in logging and lower production costs.

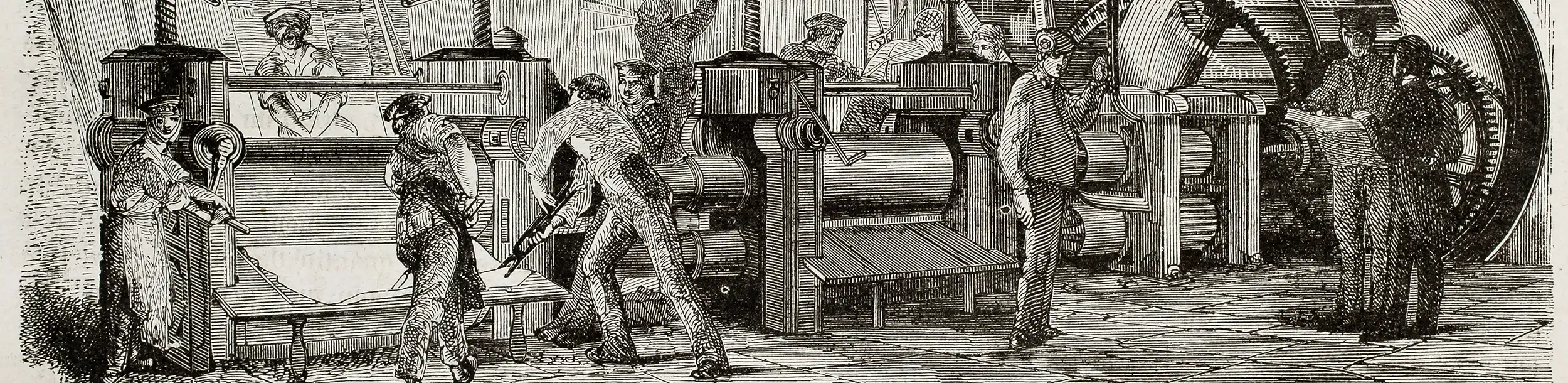

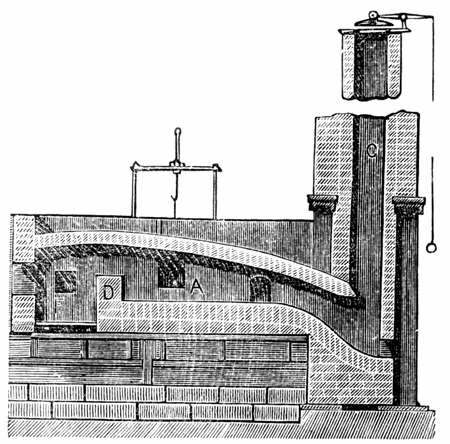

At the same time, after several centuries of using fryer furnaces, in 1784 English engineer Henry Cort develops a more efficient way of freshening steel, the so-called puddle process. The name comes from the word puddle (to turn over). It involved placing solidified pig iron in a furnace, then melting it and evenly decarburizing (decarbonizing) it while burning off unwanted admixtures. This process was aided by continuous stirring of the charge using iron rods. However, the finished "loaf" had numerous slag blemishes, which needed to be removed by repeated reprocessing. This yielded so-called welded steel or welded iron. This alloy contained less than 0.1% carbon, up to 0.25% admixtures of sulfur, phosphorus, silicon and manganese, and 1 to 2% slag. The disadvantage of the puddling method was the considerable variation in the structure and chemical composition of individual "bochness". This was caused not only by the quality of the charge, but also by the degree of experience of the workers (puddlers) themselves.

Breakthrough

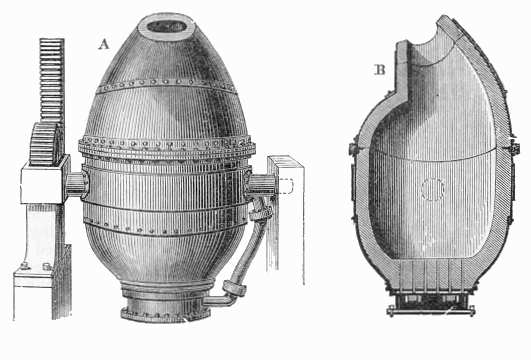

The breakthrough came in 1855, when a British man named Henry Bessemer made a real revolution in steel smelting. This was because he invented the converter, or "fuelless furnace," in which liquid pig iron is blown through with air or pure oxygen. This furnace produces tens of tons of liquid steel in a matter of minutes, while a traditional puddling furnace yielded up to 500 kilograms of steel in a single smelting that lasted several hours.

In addition, in 1858 Swede G.F. Göransson proved that - by appropriately modifying the dose of air blowing off the pig iron - different grades of alloy could be obtained. Building on this, in 1868 English industrialist and metallurgist Robert Forester Mushet developed the first tool steel called RMS high-speed steel. It is air-hardened, which gives it a higher degree of hardness. Of course, there was no shortage of difficulties when introducing the converter smelting method. They were related to the composition of the pig iron, specifically the presence of an admixture of phosphorus in it, which affected the weakness and brittleness of the final product. The solution turned out to be the use of a different type of lining of the smelting furnace itself in 1878. Dolomite was replaced with silica.

Bessemer Converter, Public Domain, https://commons.wikimedia.org/w/index.php?curid=91836

Current times

The method of smelting steel based on Bessemer's invention gave rise to modern metallurgy, which, along with the development of technology, made it possible to produce many grades of steel for various applications. Today, the steelmaking process can be divided into three stages:

- smelting,

- post-furnace processing

- casting of steel.

Steel smelting is carried out in an electric arc furnace, which provides lower energy intensity and plays an important role in recycling steel waste. The main direction of the development and improvement of steel casting technology is the transition from the traditional method of casting liquid metal into ingot moulds to the most popular method - continuous casting of steel (COS).

► Read also: "How steel is made"

Go back to blog homepage

Go back