Steel hardening process

Ordinary heat treatment

In order to change the properties of metals and their alloys, it is necessary to use one of the basic technological processes, which is heat treatment. Changes in mechanical properties are associated with a change in the structure of metals, which occurs as a result of a change in temperature over a specified period of time . Each heat treatment operation includes basic procedures, i.e. heating, quenching and cooling. To understand the rationale for conducting heat treatment, it is important to know the Fe-Fe3C iron-carbon system and the phase transformations occurring in the material under the influence of temperature change.

Volumetric hardening

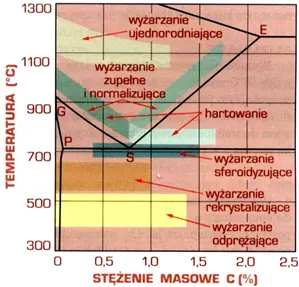

The basic and very well-known treatment is quenching. Volumetric hardening is a heat treatment operation consisting of a procedure of heating a component to austenitizing temperature, annealing at that temperature, and then cooling at a rate that allows for a martensitic or bainitic structure. The austenitizing temperature is assumed to be 30÷50℃ higher than the Ac3 temperature, which can be read from the Fe-Fe3C iron-carbon system (Figure 1).

Fig. 1. Excerpt from the Fe-Fe3C diagram with the hardening and annealing ranges of carbon steels marked (source: L. A. Dobrzanski, Fundamentals of Materials Science and Metallurgy, WNT)

The heating of a component is often carried out gradually with annealing at several intermediate temperatures, so as to avoid cracks caused by thermal stresses. The austenitizing, or annealing, temperature must also be carefully selected to avoid austenite grain growth, which would consequently affect the formation of thick-leaf martensite and thus impair the mechanical and service properties and increase the brittleness of the steel. The exact annealing temperature depends on the chemical composition of the steel, especially the carbon content.

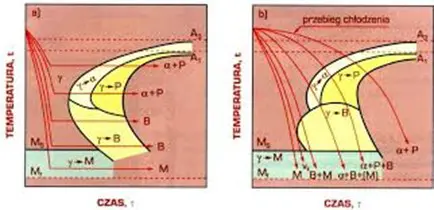

Bainitic quenching differs in the way it is cooled, which is done continuously at a rate less than critical so that the bainitic transformation can take place. After such treatment, the structure of the steel is bainite, possibly with martensite or residual austenite. This final structure of the steel has a beneficial effect on the plasticity and impact properties of the steel and improves the fatigue resistance of the steel, but at the same time lowers the elastic limit and yield strength. Bainitic hardening with isothermal transformation can also be carried out, which is a multi-step process and consists of austenite cooling, isothermal endurance in the temperature range of 250-400℃ and cooling to room temperature in still air. In this way, the product will have low thermal and structural stresses and less possibility of cracking and deformation.

Information on the structure of steel, depending on the temperature and cooling time is contained in the charts of the transformation of austenite undercooled during isothermal and continuous cooling, these are the so-called CTP (time - temperature - transformation) curves. It is on the basis of these that the cooling parameters are determined, in order to obtain the desired structure, which is consequently responsible for the mechanical properties of the finished products (Figure 2).

Fig. 2. Diagrams of transformations of overcooled austenite of sub-eutectoid carbon steel: a) CTPi with isothermal cooling, b) CTPc with continuous cooling; ɣ - austenite, P - perlite, B - bainite, M - martensite (source: L. A. Dobrzanski, Fundamentals of material science and metallurgy, WNT)

Another type of hardening is surface hardening, in which only the surface layer of the component is heated quickly and then cooled quickly. It does not induce high stresses and thermal deformation.

Additional symbols in steel designations

In the designations of steel grades, we meet additional symbols, which often specify in what condition the product is delivered to the customer.Thus, frequent designations are, for example, +N, +AR, +M, +QT.

- +N means that the product has undergone normalizing annealing, i.e. heating to a temperature of 30-50℃ above Ac3, followed by annealing at this temperature and quiescent cooling. The operation leads to a fine-grained structure, which has a beneficial effect on mechanical properties. Normalizing is primarily carried out on parts made of unalloyed structural steels to homogenize the structure, usually before further heat treatment.

- +AR means that heat treatment is not required

- +M indicates that the product was subjected to thermomechanical rolling

- +QT indicates that the product was tempered, i.e., quenching and tempering was carried out.

Go back to blog homepage

Go back