Hot rolling process for plates

Sheets are formed during the heat and plastic processing.

Heat-plastic processing is carried out in order to obtain the appropriate shape and the desired mechanical properties. Depending on the temperature at which the process is carried out, we distinguish:

- high-temperature (hot) machining

- low-temperature (cold) processing.

The limit of division is the recrystallization temperature, which is approximately 0.5÷0.6 of the melting point of the metal being deformed, expressed in degrees Kelvin. Materials with a large cross section are deformed hot. Hot rolling of sheet metal is usually carried out at a temperature of about 1200℃.

By using the right process parameters, i.e. temperature, degree of creasing and strain rate, the sheets can achieve very good mechanical and welding properties and can be subjected to further processes. By processing the sheets at high temperature and thus using less energy to deform them, hot-rolled sheets are cheaper compared to cold-rolled sheets.

Let's start with the concept of a flat product...

A flat product is a product with a rectangular cross-section, the width "b" of which is much greater than the thickness "h".

In terms of width, we distinguish between

- sheets (width b > 600 mm)

- strips (width b ≤ 600 mm).

In terms of thickness, we divide flat products into

- thick plates (thickness h > 3 mm

- thin sheets (thickness h ≤ 3 mm).

CSP continuous rolling process

The feedstock for plate production is flat ingots most often from the continuous steel casting (COS) process or formerly from rolling on a slabbing mill. The ingots are heated to a temperature of 1150÷1250℃. The rolling of ingots is carried out in a continuous rolling mill on a strip sheet.

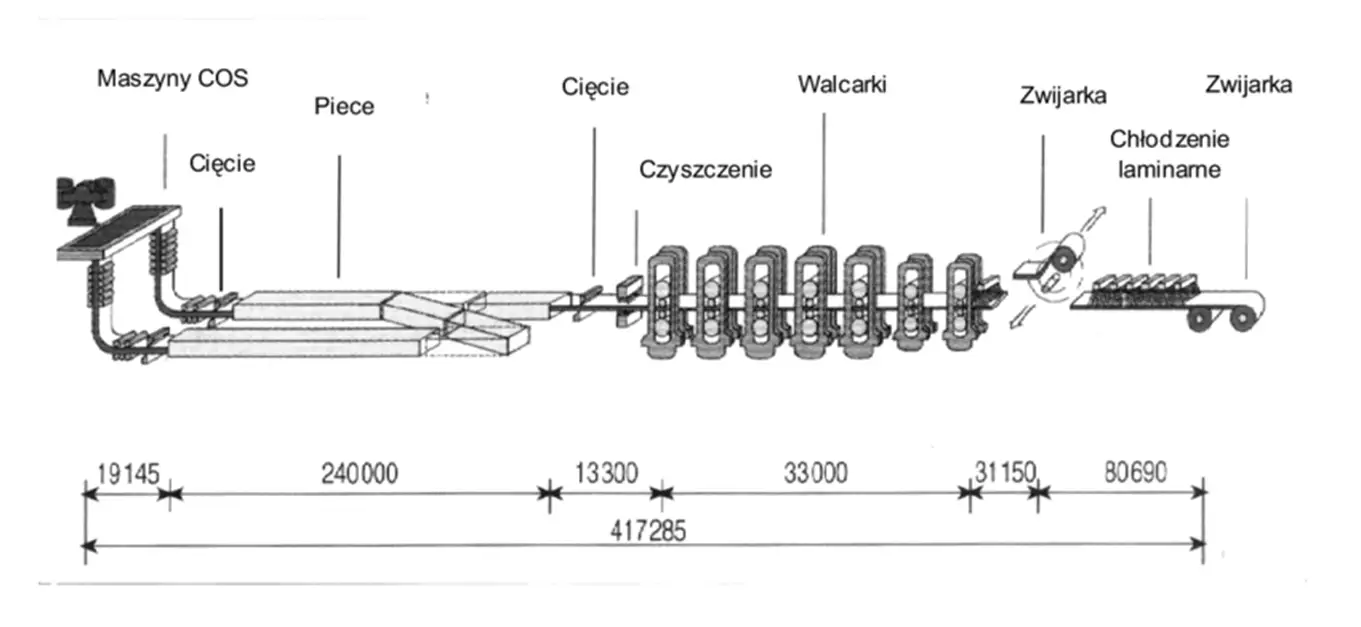

Nowadays, the COS process is combined with the hot rolling process into one integrated system, such as the CSP (Figure 1) method (Compact Strip Production).

Fig. 1. Installation of CSP - Compact Strip Production at Thyssen Krupp Stahl AG (source: M.Dziarmagowski, T.Kargul, M.Skalski, Development of an integrated strip sheet production process)

Such a method of sheet metal production significantly shortens the production line and the time from the moment the metal is drained into the ladle to the moment the finished product is obtained in the form of a strip.

After exiting the COS machine, the strip is cut with knives and transferred on self-tots to a heating furnace to equalize the temperature across the section. Behind the furnace, another shear is mounted, as well as a scaling device.

The rolling line consists of a group of seven quarto rollers. In the group of seven rolling mills the rolling process is carried out continuously. In the quarto rolling mill, the basic deformation is realized, during which the band thickness is reduced. The sheet after leaving the last cage can be subjected to regulated cooling by water spray in a laminar cooler, after which it is rolled into coils. In a typical CSP line, the quarto rollers form a continuous group and, in addition, the condition of continuous material flow between the rollers must be met.

The rollers are computer-controlled based on measurements of band shape, temperature, rolling speed and roll pressures. The integrated rolling system ensures reduced energy consumption at the expense of use of heat contained in the ingot, reduces environmental pollution, eliminates the pre-rolling system, shortens the rolling line and reduces investment costs.

Other sheet metal fabrication methods

The sheet metal fabrication process has evolved with the development of industry and technology, so various fabrication methods are known, which differ, for example, in the method of heating (induction, arc, additional heating furnace). Line modifications are made to avoid sheet cracking and to increase production efficiency and reduce costs.

Currently known include.

- cSP process - Compact Strip Production

- iSP process - Inline Strip Production

- dSP process - Direct Sheet Plant

- dSC process - Direct Strip Casting

- kTN process - Krupp Thyssen Nirosta

The hallmarks of the ISP line are the so-called "post-casting" of the cast strip, i.e. the deformation of the core of the ingot in a semi-liquid state and direct rolling at high temperatures after the strip exits the COS line. Other methods also include: the use of reheating the band in induction furnaces and the use of Cremona-type retractors placed in the furnaces, upstream of the finishing line of the rolling mills, to equalize the temperature across the coil and reduce the temperature difference between the beginning and end of the band.

Hot-rolled sheets and strips are widely used in the automotive, aerospace, energy, construction, or household appliance industries. In addition, they are a feedstock for cold-rolling sheets and strips and for the cold manufacture of bent sections of open and closed types. Sheets and strips are rolled into coils.

Advantages and disadvantages of hot rolling

Advantages:- full recrystallization of the material occurs

- the plastic resistance of the metal is very low, so the ductility of the metal is high and complex shapes can be easily obtained,

- a large amount of energy is consumed to heat the metal to the forming temperature

- the surface of the steel is covered with a layer of scale, which must be removed.

Go back to blog homepage

Go back