Steel cold drawing process

What is the process of manufacturing round and square drawn bars?

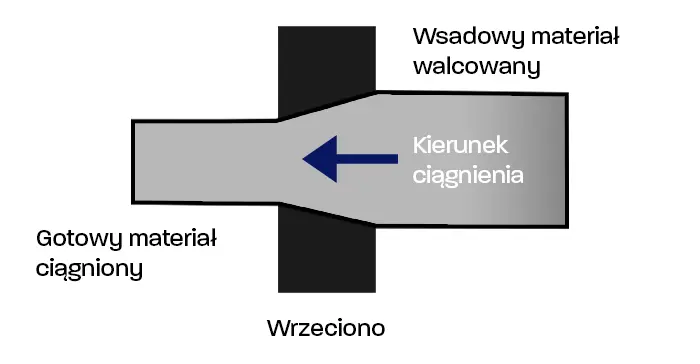

Drawing is one of the methods of cold, hot or warm metal forming, which involves pulling material through a tool called a drawing die or through a tool assembly consisting of a drawing die and a mandrel with a cross-section smaller than that of the feedstock.

In the most commonly used process - cold drawing - the feedstock material, which is wire rod or wire passes through a number of gradually decreasing working holes of a drawing mesh with a specially shaped profile, and then winds up on the drum or disc of the drawing machine. As a result of this process, there is a change in the cross-sectional area or cross-sectional shape, a change in linear dimensions, an increase in dimensional accuracy, surface smoothness, as well as a change in the mechanical and physical properties of the resulting product. As a result of the transition between holes, significant contact friction is created, which is reduced through the use of lubricants. The agents used reduce energy consumption and increase the life of the drawing dies, as well as having a beneficial effect on the surface quality of the final product.

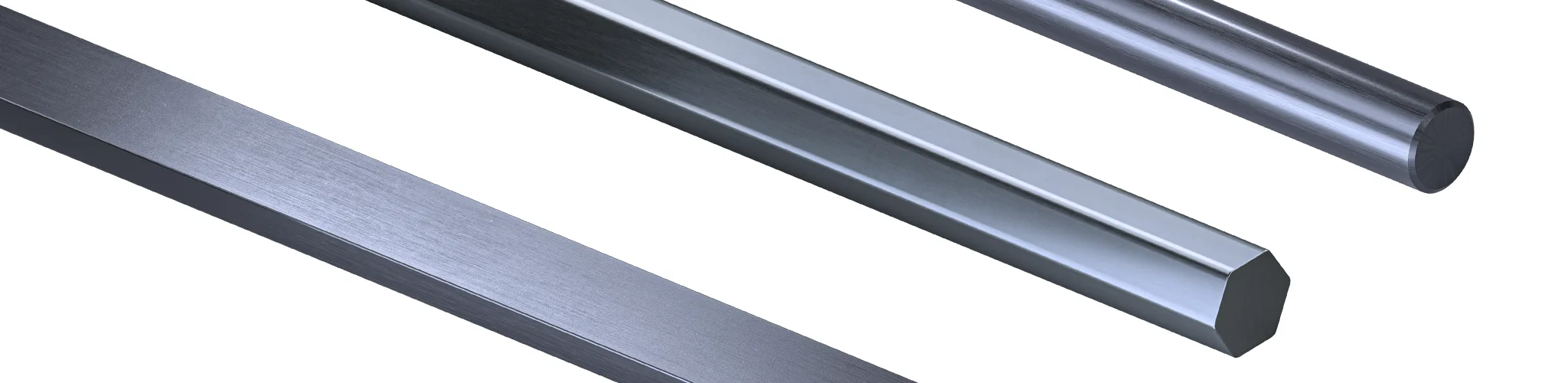

The process is used to produce wires, round bars as well as hexagons, flat bars and seamless or seamed pipes. The cold drawing method reduces the diameter of hot-rolled or hot-extruded materials and relatively reduces the size or changes the cross-sectional shape of the material being deformed. The plastic deformation occurring in the drawing process causes the material to strengthen, and this increases the strength properties of the finished product.

Materials used in the drawing process

The most common materials processed in the drawing process are:

- low-carbon steels for further plastic processing and for making screens, wire cloth, etc.

- steels with medium and high carbon content, among others, for making springs, ropes, etc.

- structural and tool alloy steels

- non-ferrous metals, e.g. brasses, bronzes, copper and its alloys, aluminum and its alloys.

Kobo method

An alternative to conventional drawing is the Kobo method, which, thanks to optimal process conditions, makes it possible to reduce the work of deformation, reduce tool wear and avoid inter-process annealing operations. In the Kobo method, it is possible to achieve a very large deformation during a single sequence of operations.

The future of the drawing process

The development of the modern drawing process is made possible by new technologies that enable the shaping of modern materials with enhanced mechanical and technological properties, improve the quality of products and reduce manufacturing costs. Currently, the rapid development of electronics uses the drawing process combined with heat treatment, the wire is heated by electrostatic method.

The industry is constantly showing demand for various types of steel wires and rods and products made from them. The ever-growing energy, armaments and automotive industries, as well as the construction, machine tool, aerospace industries are using products made by this method.

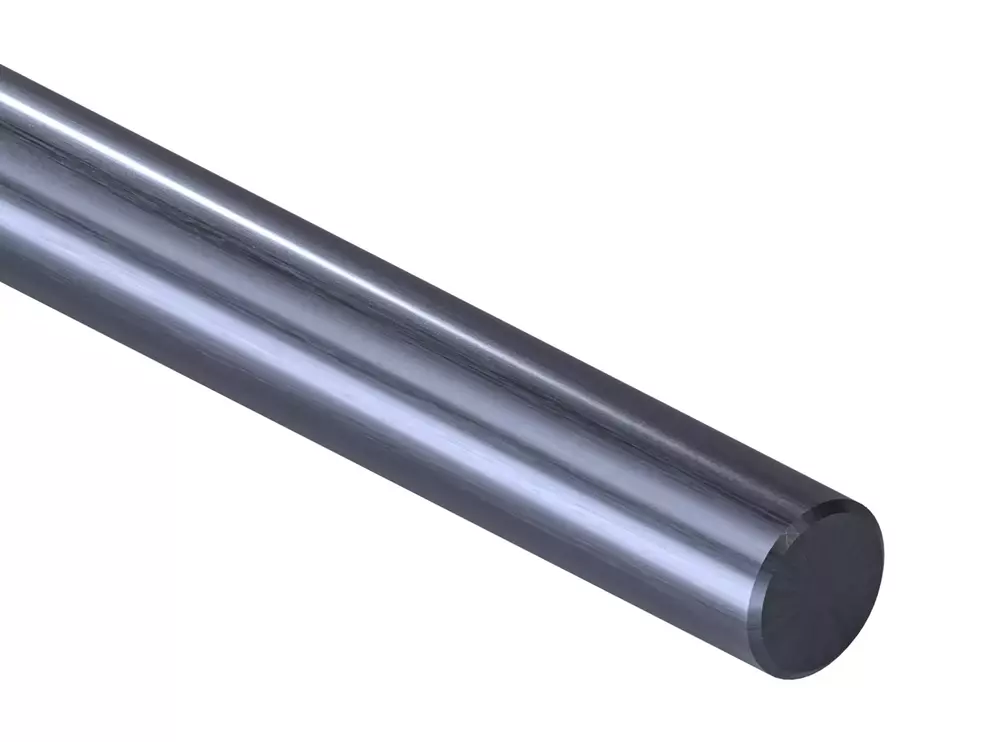

Drawn round bars

Round drawn steel bars are extremely versatile, so they can serve a variety of applications. After the cold-drawing process, the surface is free of imperfections, and the bar becomes stronger, perfectly straight, and less ductile.

Drawn flat bars

Drawn flat bars (flat bars) are flat bars that are cold rolled continuously. The production of drawn flat bars involves passing a flat bar through a continuous hole with a smaller diameter than the feedstock bar. After the drawing process, the bar obtains a smaller diameter and greater length, and better mechanical properties.

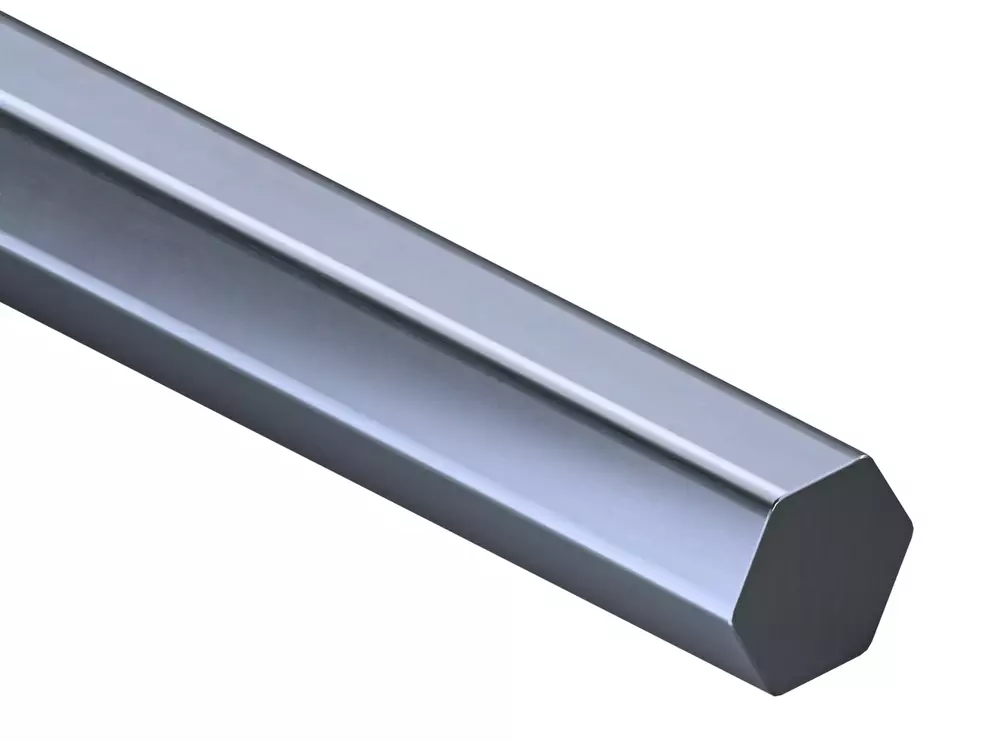

Drawn hexagonal bars

Hexagonal drawn bars (hexagonal steel bars) are materials that we obtain from a technological process known as drawing. This process is a type of cold processing that involves drawing basic products like wire rod. The material is placed in a continuous hole with a diameter that is smaller than its own.

The application of drawn hexagonal bars is mainly solid fencing structures such as railings, fences, wickets and gates.

Back to the main blog page

Back to blog