Casting

One of the plastic forming processes is die forging, which takes place at elevated temperatures or hot, during which products obtain the shape of a die. Due to the high cost of dies, this process refers to the manufacture of products on a mass scale most often for the automotive or engineering industries. The advantages of this type of forging are, first of all, accuracy of manufacture, good surface quality, high strength properties of products, obtaining parts with complex shapes and high repeatability, with small technological allowances.

The course of the process begins with the heating of the material in a continuous induction furnace, followed by preliminary shaping in forging mills and final forging on hammers or forging presses. Due to hazardous working conditions, some operations are performed by manipulators and industrial robots.

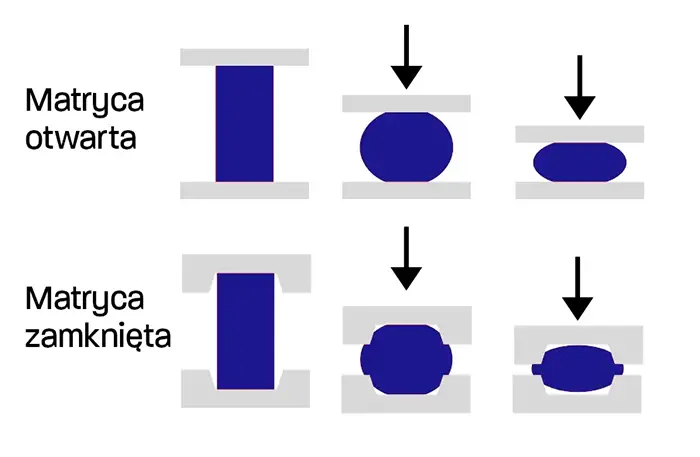

Die forging methods

- with a flash,

- without forging.

Division by the device on which the process is carried out:

- forging on hammers,

- forging on mechanical presses,

- forging on hydraulic presses.

Special forging methods:

- forging on forging machines, involves inflicting a large strain corresponding to the reduction of the cross-section in the bladder by inflicting a large number of small strains corresponding to the reduction of the cross-section in a single blow. The material can be fed with simultaneous rotation, e.g. when forging bars of circular cross-section, or without rotation, e.g. when forging bars of polygonal cross-section.

- forging on forging machines, where the charge is usually a bar, which is placed in a closed blank formed by two dies, one of which is fixed and the other is movable. The advantage of this method is that it produces forgings of repeatable shape and dimensions.

- forging on automatic forging machines, is carried out for large products hot or for small ones cold. The feedstock is wire rod or wire. This method is most often used for the manufacture of bolts, nuts, rivets, pins, bearing rings, bushings.

The die forging method is used to make many parts, including:

- gears,

- road wheels,

- crankshafts,

- various types of fasteners, joints of load-bearing elements,

- forgings, which are used to build industrial machinery, process lines, vehicles and aircraft,

- others.

Go back to blog homepage

Go back